Etchback

Check for the etching process that removes the wiring connected to the electroplating on the pad during the package manufacturing process.

- Etching / Plating Bar Layer Definition

- Select Etching layer for Top side: Select the etching layer drawn on the top side.

- Select Etching layer for Bottom side: Select the etching layer drawn on the bottom side.

- Select Etching layer for Inner layer: Select the etching layer drawn on the inner layer.

- Select Platting Bar layer: Select the layer where the platting bar area is drawn.

- Checking: Set the checking rules for each Top, Bottom and Inner layers.

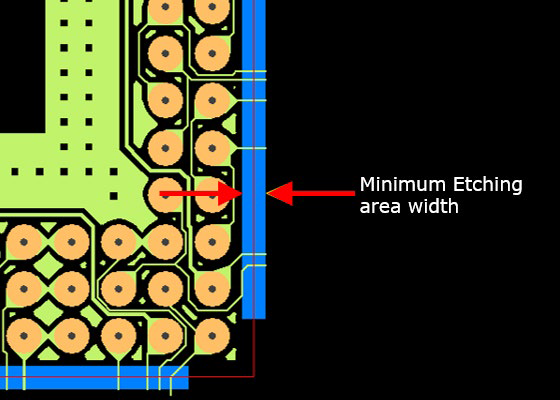

- Minimum Etching area width: Minimum width checking of objects drawn

on the etching area.

Figure 1.

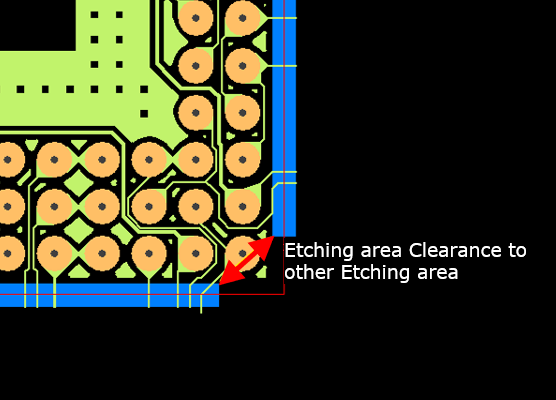

- Etching area Clearance to other Etching area: Minimum clearance

checking between objects drawn on the etching area.

Figure 2.

- Etching area Clearance to user Defined Layer Objects: Clearance checking between objects drawn in the etching area and in the user defined layer.

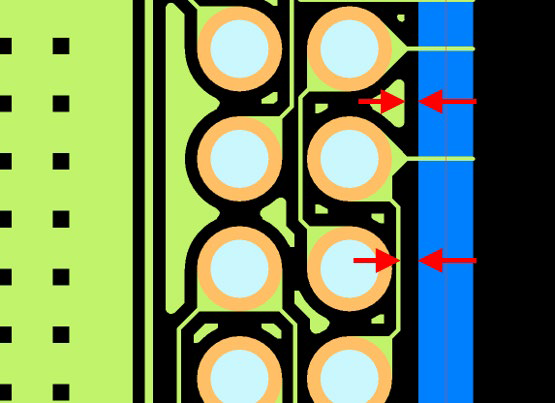

- Etching area Clearance to Pattern: Clearance checking between

etching area and pattern but excluding the pattern segment directly

connected to the etching area.

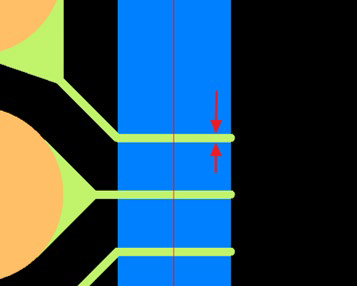

Figure 3.

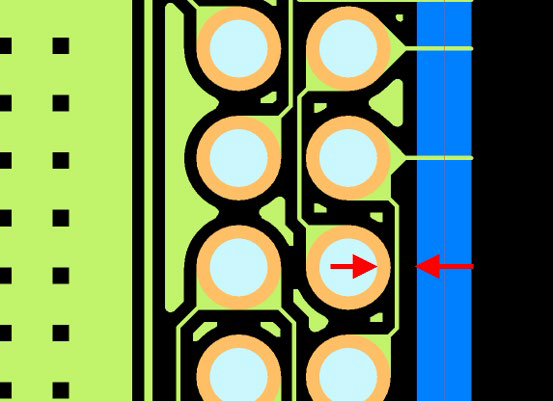

- Etching area Clearance to Copper: Clearance checking between etching area and copper polygon.

- Etching area Clearance to Solder Mask: Clearance checking between

etching area and solder mask.

Figure 4.

- Check Pattern width in Etching area: Check whether the pattern

overlapped with the etching area is designed within the user defined

width.

Figure 5.

- Checking Plating Bar connection with Net which connected with S/R Pad: Check whether the Net connected to S/R opened pad is connected to the plating bar.

- Checking Short Nets after Etching: Check whether the shorted net exists after the etching process.

- Minimum Etching area width: Minimum width checking of objects drawn

on the etching area.