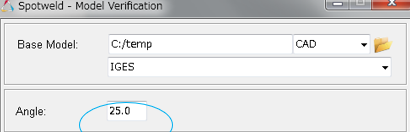

spotweld

Specify defaults for the spotweld check functionality of Model Verification.

General Settings

- angle

- Feature angle of the faces of FE.

- Slide-number

- The starting number shown in the top corner of the PowerPoint file.

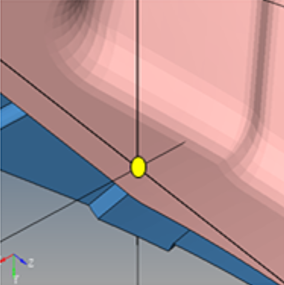

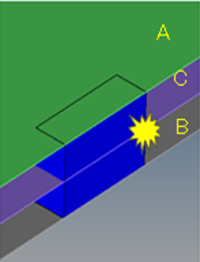

Figure 1. - input

- Initial directory for the Input file path.

- output

- Initial directory for the report output path.

- action

- User action type to be executed.

- Check

- Only intersection check will be executed, no reports.

- Report

- Only Reports will be generated from the previous check.

- Both

- Check and Report generation will be executed in a sequence.

- mode

- Default options for Run type.

- interactive

- Check executed in the front ground HyperMesh session

- background

- Check executed in the background HyperMesh sessions. Automatic restart executed. If errors occur, the errors will be displayed in the browser as "Crash" keyword.

- vip-format

- Space or 8-digit separated format.

- resolveconflictingpid

- 5 digits or 7 digits format correction.

- realize-check

- Ignores failed spot welds during the check.

- allow-multiple-issues

- All checks on all spot welds. There may be issues on the same welds.

- extract-spot-cad

- Converts CAD points/solids to the spot weld file. A copy of the spot weld vip file will be stored in the CAD folder.

- extract-spot-cad-option

- Converts point/solid entities to spot weld file.

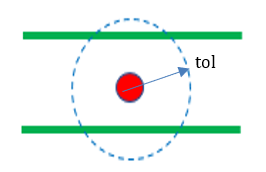

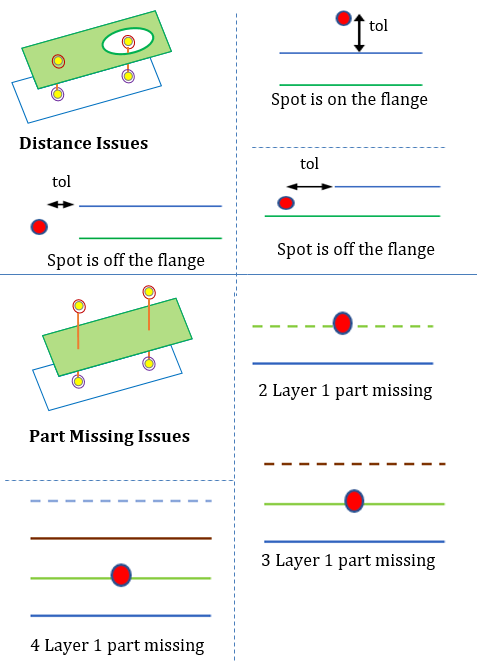

- realize-tolerance (tol)

- Allows searching the nearest spot on the same layer or different layer

or bot/all duplications.

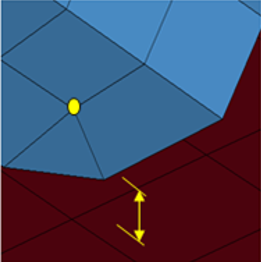

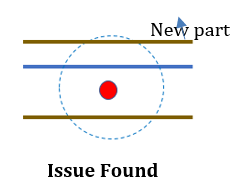

Figure 2.

Closest

- do-check

- Turn OFF or ON the check

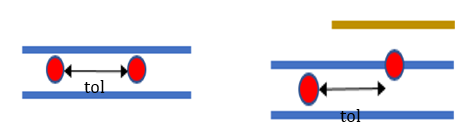

- Tolerance (tol)

- Distance between two spot welds less than/equal to this tolerance are

reported as duplicates. Distance is calculated after projecting to

normal direction.

Figure 3. - checktypes

- Allows searching duplicate spot welds on the same layer (same weld plates) or different layers or bots/all duplications.

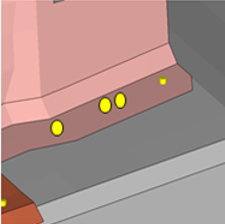

Figure 4.

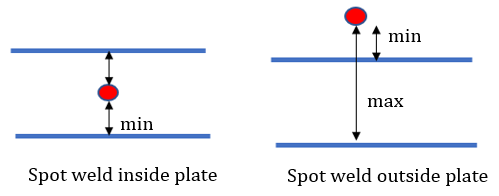

Gap

- do-check

- Turn OFF or ON the check

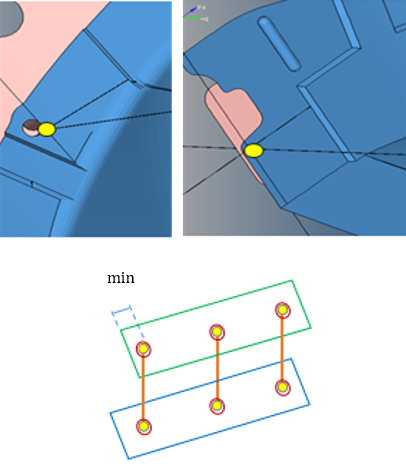

- min

- Minimum gap between Spot location and the weld plates.

Figure 5. - max

- Maximum gap to be considered between Spot location and the weld plates. This value is added to filter some spotwelds which are too far from the model.

Figure 6.

Single-Layer

- do-check

- Turn OFF or ON the check

Figure 7.

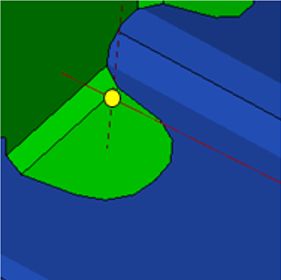

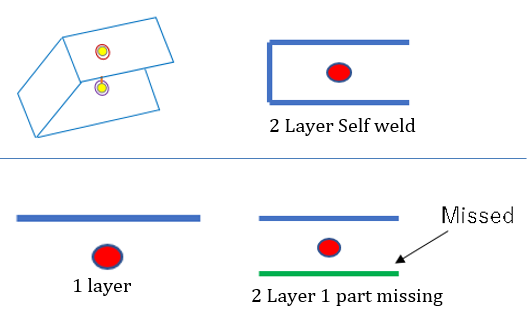

Multi-Layer

- do-check

- Turn OFF or ON the check

- threshold

- Maximum allowed spot weld layers.

Figure 8.

hm-issue

- do-check

- Turn OFF or ON the check

- Tol

- realize-tolerance (tol)

Figure 9.

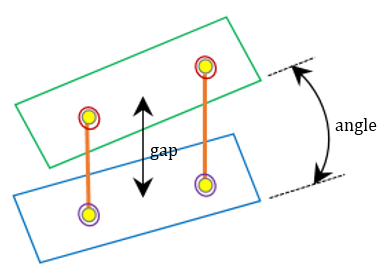

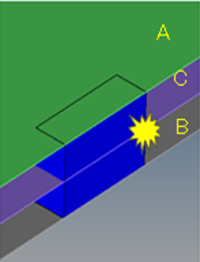

Parallel-flanges

- do-check

- Turn OFF or ON the check

- angle

- Maximum angle between two plates at spot location.

Figure 10. - max-gap

- Maximum physical gap between two plates at Spot location.

Figure 11.

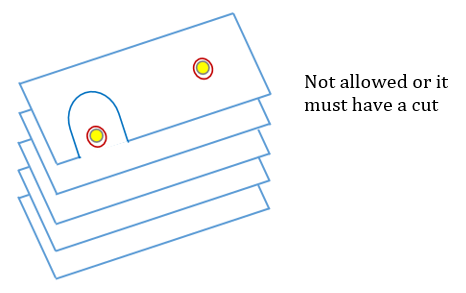

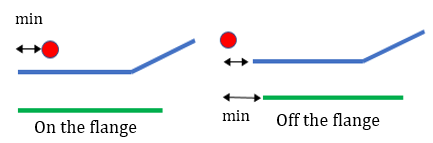

Incorrect-Location

- do-check

- Turn OFF or ON the check

- min-distance (min)

- Minimum distance allowed from feature-line to the spot location.

Figure 12.

Figure 13.

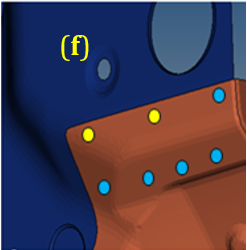

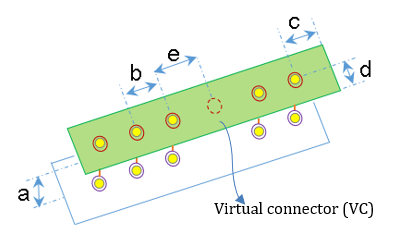

Few-Connections

- do-check

- Turn OFF or ON the check

- Proximity (a)

- Search tolerance for realizing spot weld on the flanges, it is global pitch.

- pitch-spacing (b)

- Average pitch distance for creating spot weld on flange.

- pitch-offset (c)

- End offset distance on both side of the flange.

- pitch-edge-distance (d)

- Offset distance from the edge of the flange.

- search tolerance (e)

- Tolerance for searching Virtua connectors from existing connectors created from the above parameter.

- hole-diameter (f)

- Search tolerance for finding nearest Bolt holes to avoid finding the

issue.

Figure 14.

Figure 15.

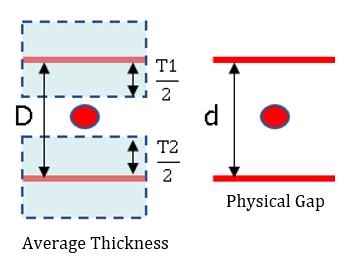

Flange-gap

- do-check

- Turn OFF or ON the check

- limit

- +/- ratio of shortest gap between flanges at connector to average

component thickness value. It is also % of deviation.

Figure 16.

Figure 17.

Intersection

- do-check

- Turn OFF or ON the check

- spot-layers

- Maximum number of layers considered for this check.

Figure 18.

Figure 19.

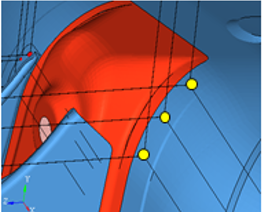

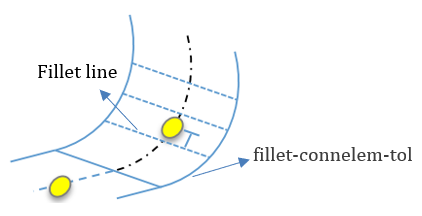

Fillets

- Fillet identification angle

-

Figure 20. - do-check

- Turn OFF or ON the check

- fillet-connelem-tol

- Search tolerance for searching the nearest fillet edges to the

connector.

Figure 21.

Figure 22.

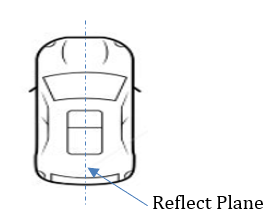

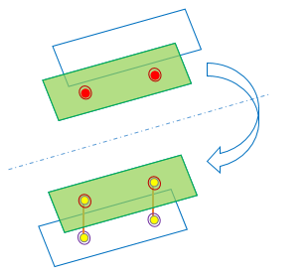

Reflect

- do-check

- Turn OFF or ON the check

- reflect-plane

- Reflecting plane for the model which the spot welds are reflected and

checked again for realization.

Figure 23. - origin

- Origin value. (for XY plane, origin is constant Z value)

Failed spot welds are reflected at reflect-plane and re-realized, if successful in realization, it is identified as an issue.

Figure 24.

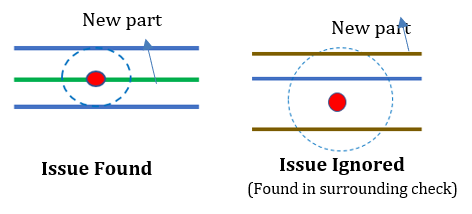

surrounding

- do-check

- Turn OFF or ON the check

- spot-layers

- Maximum number of layers considered for this check.

Figure 25.

Figure 26.