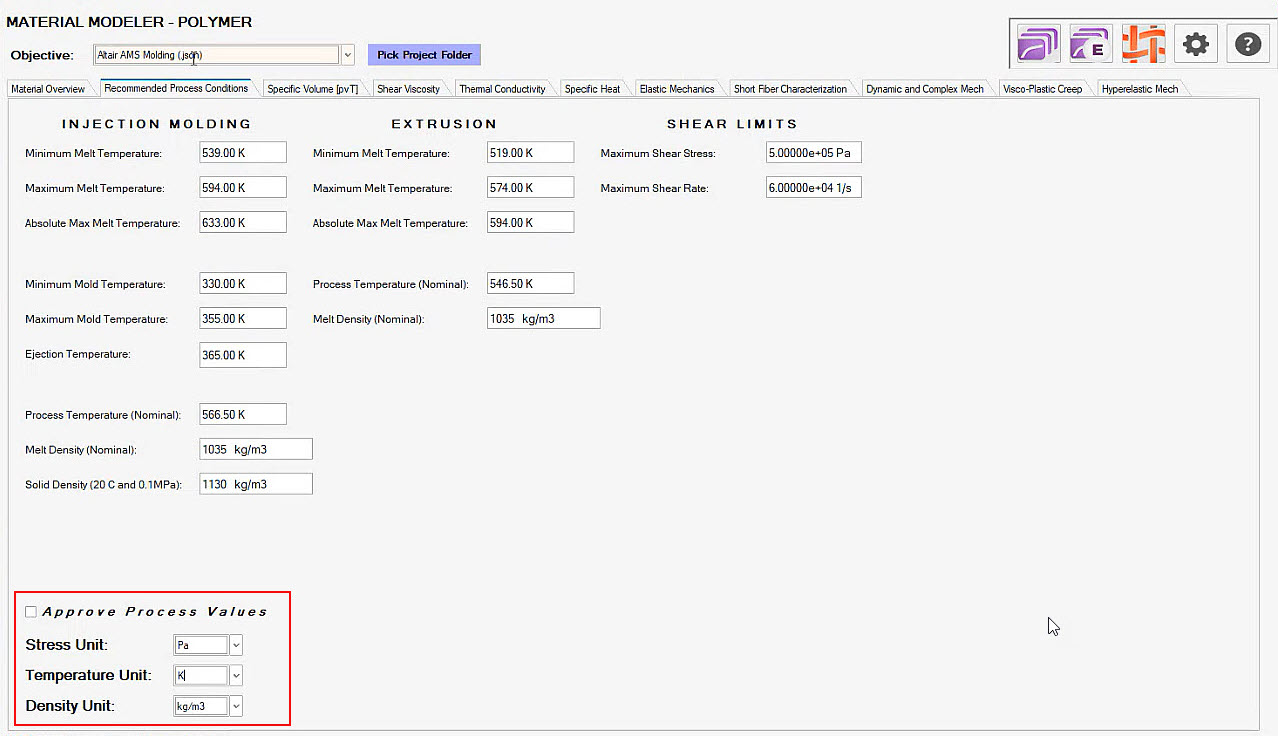

Recommend Process Conditions

At the start of the process, default settings for molding and extrusion are loaded based on the polymer family. Each type of thermoplastic polymer has default values for parameters like minimum and maximum melt temperatures. These values are pre-set defaults based on common standards, and are meant to be replaced when specific values are known. These serve as reference values in simulation setup and in post processing, depending on the specific quantity.

Adjusting Units:

Units for various values can be changed to match a report from a lab or other source

before approving the process values. For file output, units are controlled in the

export panel of the Material General Information tab. Here’s

how to customize:

- Modify the required units for Stress, Temperature, and Density using the corresponding list.

- The units for shear rate are always per second (s⁻¹), so that measure is fixed.

- These adjustments allow the entry of values without the need for conversion. Despite the fact that data can be viewed and entered in different units, the software executes all background calculations in a consistent unit system (MKS).

-

Figure 1. Recommended Process Conditions and Values

- After making adjustments, click Approve Process Values to finalize preferences for the process. This ensures all values are saved for export. .

- Once the data fit is approved for Viscosity, the Melt Viscosity button on the Material Overview tab changes to green as an indicator.