Submitting a Job

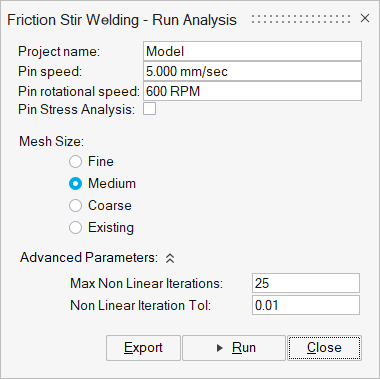

Define and run an analyis using the Run Analysis tool.

-

From the Friction Stir Welding ribbon, click

on the Analysis tool in the

Run group.

on the Analysis tool in the

Run group.

-

In the Analysis Parameters dialog, define parameters

accordingly.

Note: To see Advanced Parameters options, you must enable it in Preferences.

Note: To see Advanced Parameters options, you must enable it in Preferences. -

Click Run to submit the job.

The status of the run is displayed.

-

Click Export to complete the pre-processing.

The process stops after the data decks for the solver are generated.

Analysis Parameters Settings

- Project name

- The data deck is written with "name" as a prefix. It is written in the same folder where the model is saved. Avoid using special characters as files will be created using this name.

- Pin speed

- The speed at which the pin travels across the plate.

- Pin rotational speed

- The speed at which the pin spins, measured in RPM.

- Pin Stress Analysis

- Check this box to run pin deflection analysis and examine pin deformation and stresses.

- Mesh Size

- Medium is the preferred option. If the model has many fine features, selecting Fine is recommended. If it is a simple model, Coarse option can be used. To start from existing mesh, click on Existing and select the mesh file.

- Advanced Parameters

-

Note: Must be enabled in Preferences to see these options.

Max Non Linear Iterations Maximum iterations per time step. Nonlinear iteration loops stop when the convergence criterion set by Nonlinear Iteration Tolerance is met. If the solution is not convergent, the loop will stop when it reaches this maximum value. The default value is 25.

Non Linear Iteration Tol Tolerance for nonlinear iterations. The default value is 0.001. This value defines the convergence criteria for nonlinear iterations.

For a fast and reasonably accurate analysis, nonlinear iteration tolerance can be increased to 0.005 or even 0.01.