HL-T: 1080 Random Fatigue Analysis Using PSD Stresses

Tutorial Level: Beginner

In this tutorial you will:

- Import a model to HyperLife

- Check that the FE result file contains a random response subcase with PSD stresses (Segalman Vonmises or Abs Max Principal Stresses)

- Select the SN module with a Random (PSD Stresses) loading type and define its required parameters

- Create and assign a material

- Create a random response fatigue event

- Evaluate and view results

Before you begin, copy the file(s) used in this tutorial to your

working directory.

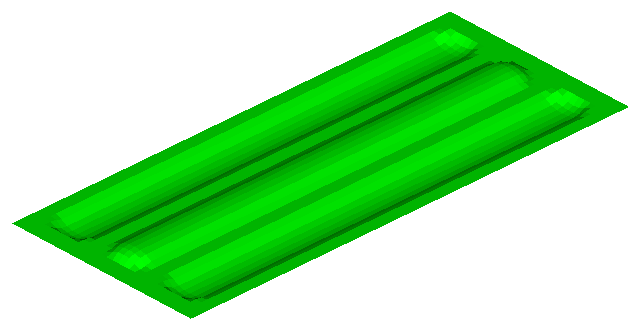

Import the Model

-

From the Home tools, Files tool group, click the Open Model tool.

Figure 1.

-

From the Load model and result dialog, browse and select

HL-1080\Plate_Random.h3d for the model

file.

The Load Result field is automatically populated. For this tutorial, the same file is used for both the model and the result.

-

Click Apply.

Figure 2.

Tip: Quickly import the model by dragging and

dropping the .h3d file from

a windows browser into the HyperLife

modeling window.

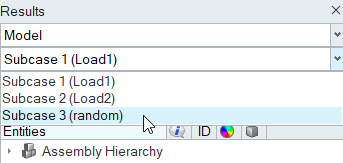

Check That the FE Result File Contains a Random Response Subcase with PSD Stresses

Both are needed to run this type of analysis.

-

From the Results Browser, click the second drop-down menu

and select Subcase 3 (random).

If the Results Browser is not open, click from the menu bar.

Figure 3.

-

From the View Controls toolbar, click

.

The Contour panel opens.

.

The Contour panel opens. -

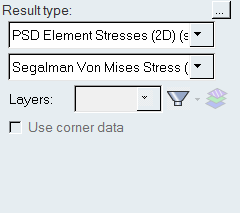

From the panel area, select PSD Element

Stresses (2D) (s) from the first Result type drop-down

menu.

Figure 4.

-

Click Apply.

The model is contoured.

- Observe the PSD element stress plot in the modeling window then select Clear Contour in the panel area.

- Exit the Contour panel.

Define the Fatigue Module

-

Click the SN tool.

The SN tool should be the default fatigue module selected. If it is not, click the arrow next to the fatigue module icon to display a list of available options.

Figure 5.

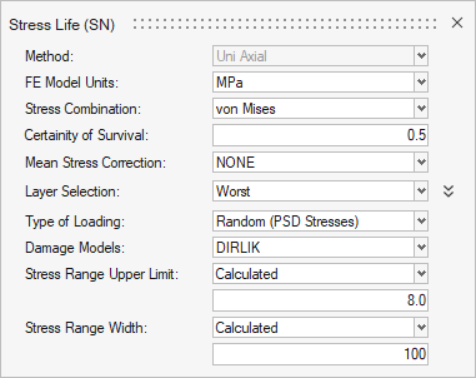

The SN dialog opens. -

Define the SN configuration parameters.

Figure 6.

- Exit the dialog.

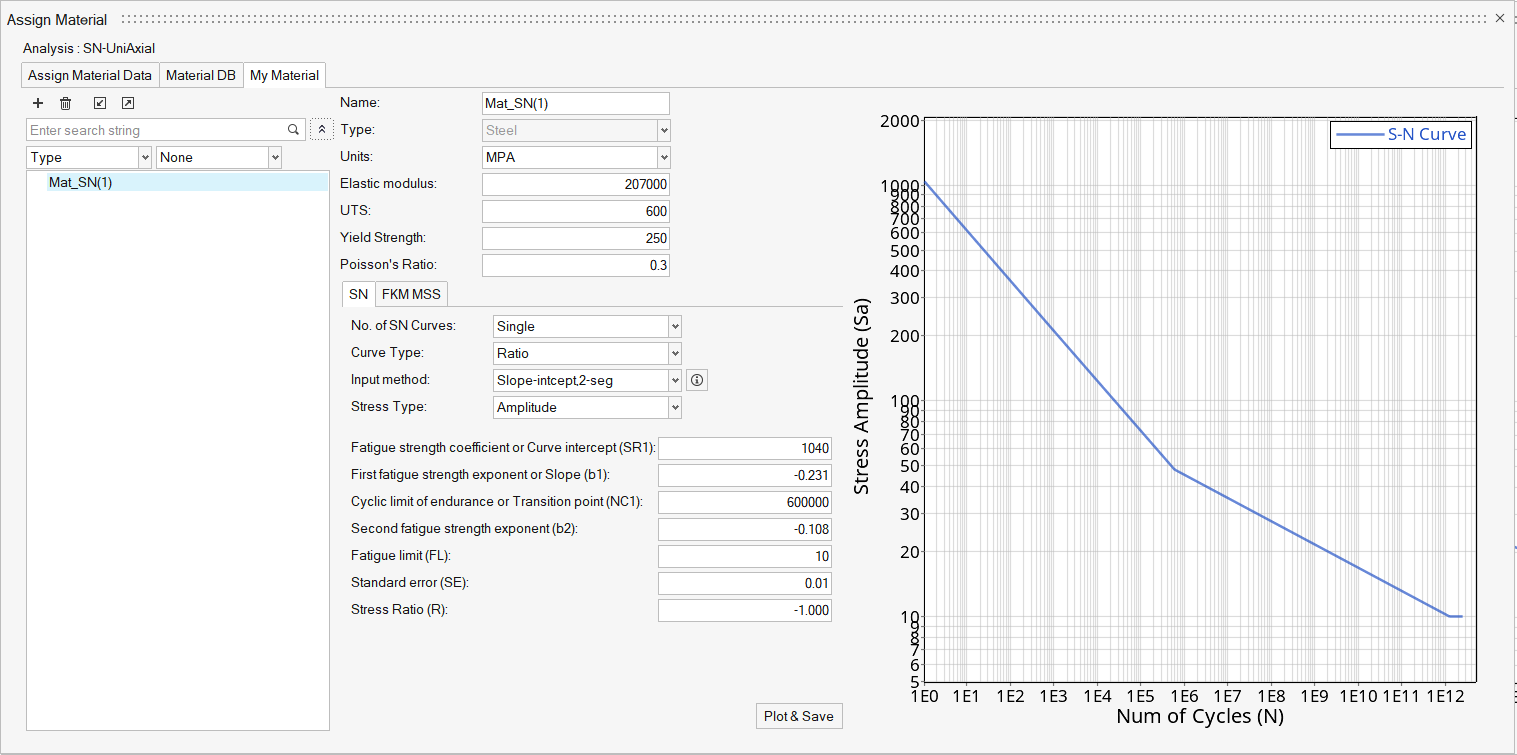

Assign Materials

-

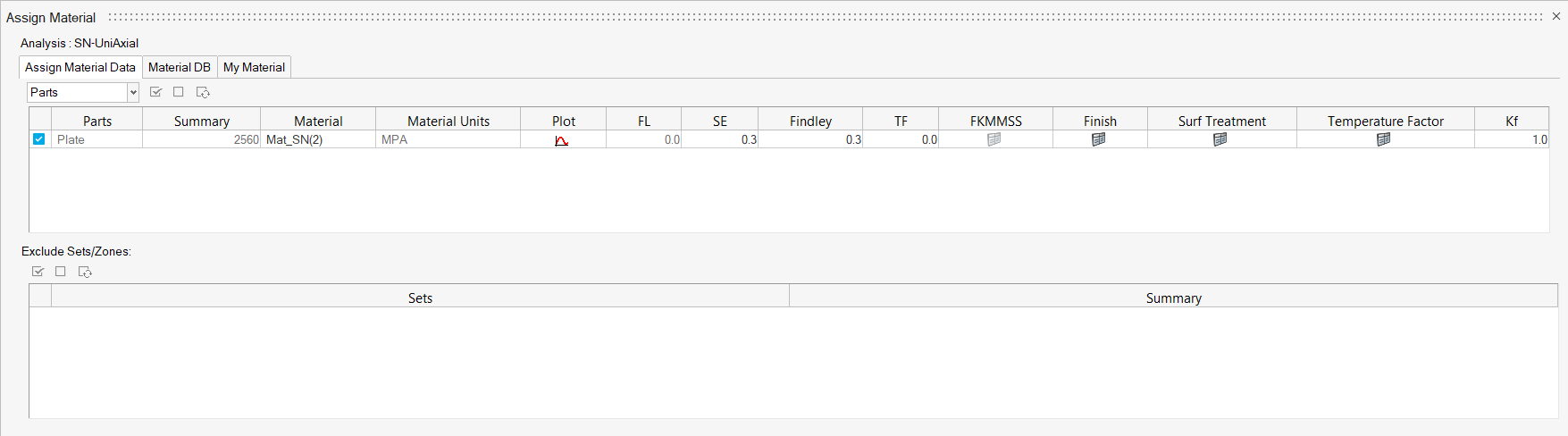

Click the Material tool.

Figure 7.

The Assign Material dialog opens. - Activate the checkbox next to the part Plate.

-

Create a new material.

- Right-click on Mat_SN("n") and select Add to Assign Material List.

-

Return to the Assign Material Data tab and select

Mat_SN("n") from the Material drop-down menu for

Plate.

The Material list is populated with the materials selected from Material Database and My Material.

Figure 9.

- Exit the dialog.

Create a Random Response Event

-

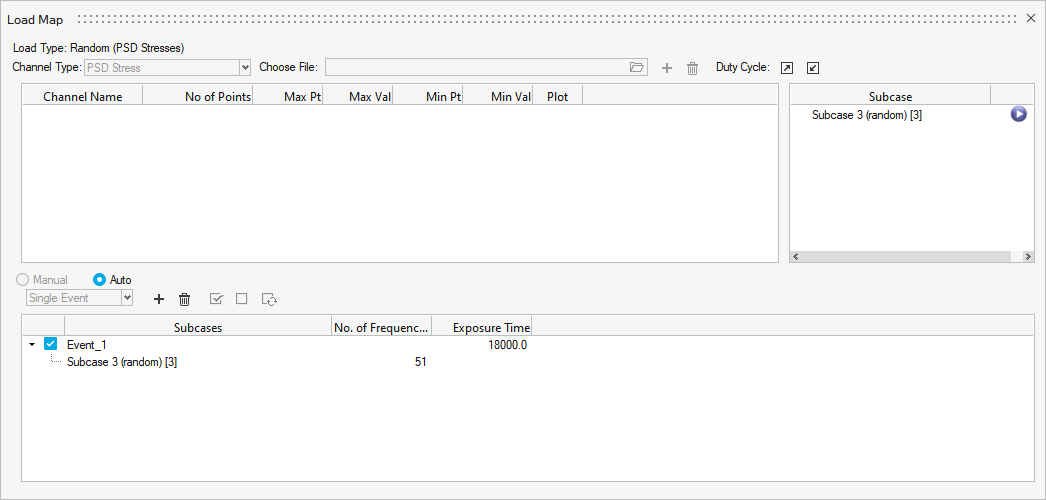

Click the Load Map tool.

Figure 10.

The Load Map dialog opens.By default, PSD Stresses is the selected Channel Type and can not be changed.

- Select Subcase 3 (random).

-

On the bottom half of the dialog, click

to create an Event_1 header.

Subcase 3 is listed under the event.

to create an Event_1 header.

Subcase 3 is listed under the event. -

Activate the Event_1 checkbox.

Figure 11.

Note: You can only select one random response subcase per event. - Exit the dialog.

Note: If Mean Stress correction is to be applied, a static subcase, if present in the

result file, will be listed in the Subcase window and can be drag and dropped onto

the event (no channel is required to be paired).

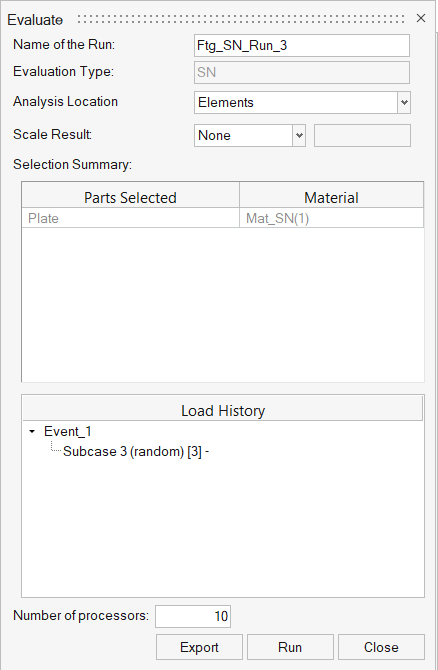

Evaluate and View Results

-

From the Evaluate tool group, click the

Run Analysis tool.

Figure 12.

The Evaluate dialog opens.Figure 13.

- Optional: Enter a name for the run.

-

Click Run.

Result files are saved to the home directory and the Run Status dialog opens.

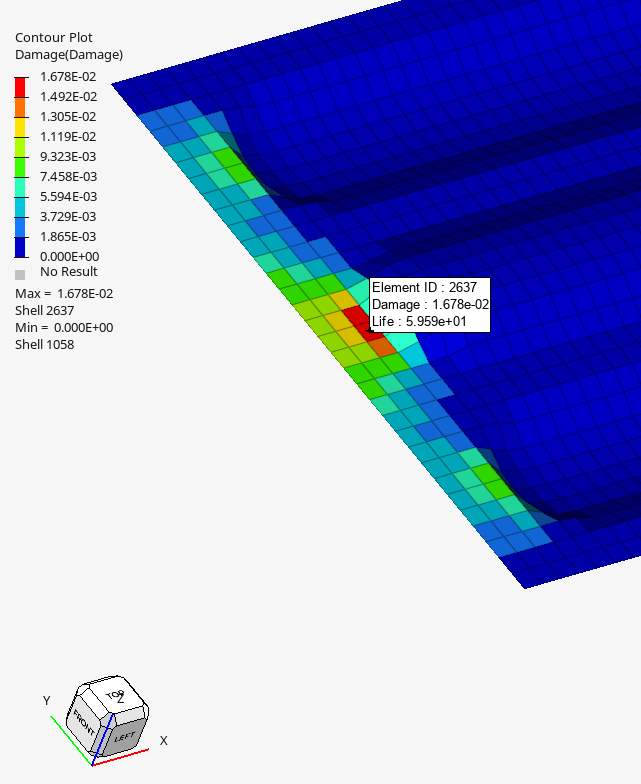

- Once the run is complete, click View Current Results.

-

Use the Results Explorer to

visualize various types of results.

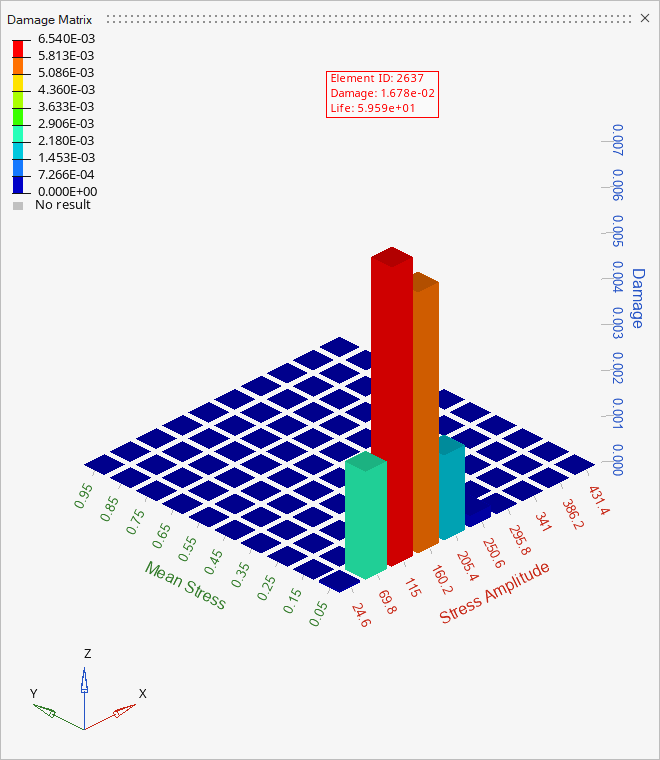

Figure 14.

Figure 15.