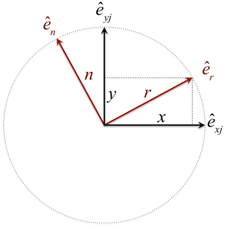

| Deforming vector |

|

| Unit vector along radial deformation |

|

| Unit vector perpendicular to deformation |

|

| Bushing radial deformation |

|

| Bushing tangential deformation |

|

| Deformation velocity vector |

|

| Bushing radial deformation velocity |

|

| Bushing tangential deformation velocity |

|

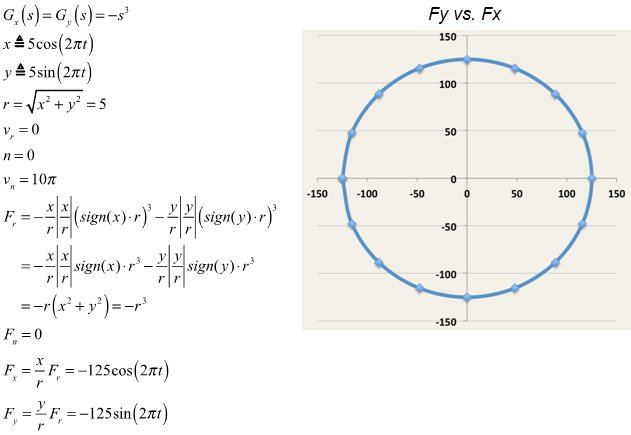

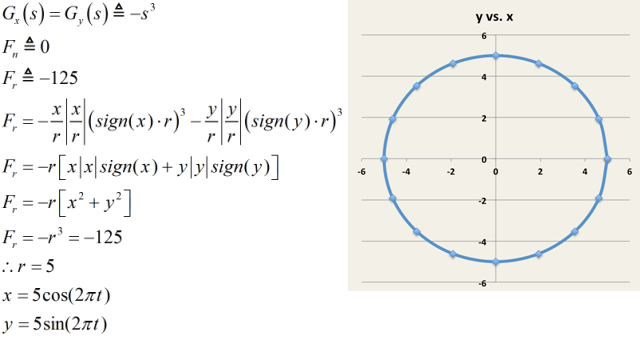

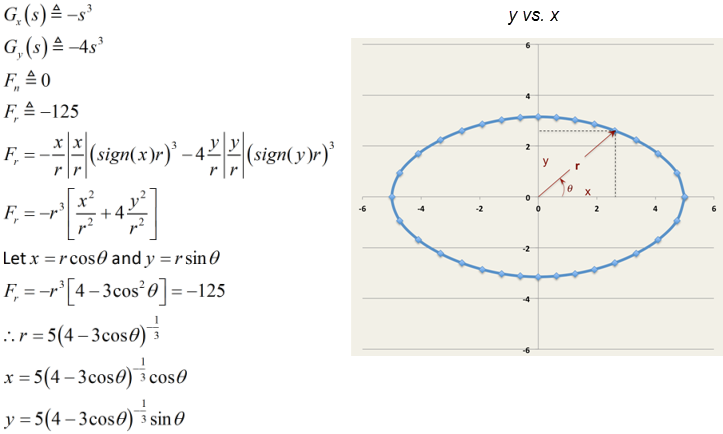

| Bushing force vector |

|

| Radial force |

|

| Tangential force |

|

| Force in the x-direction |

|

| Force in the y-direction |

|