Lead

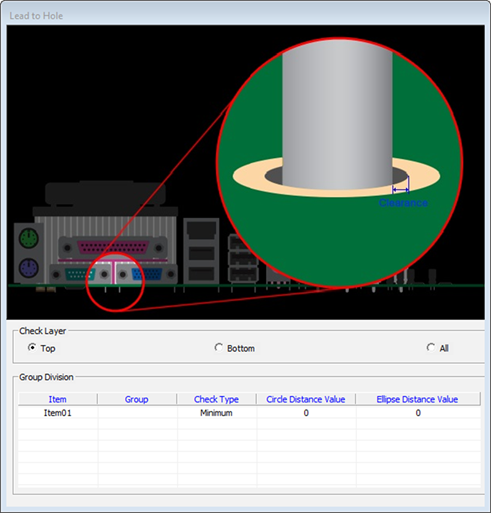

Lead to Hole

Checks the clearance between the DIP type component’s lead and hole. If there is not

enough clearance, it results in soldering defect.Figure 1.

- Check Layer: Select checking target layer.

- Item: Input item name.

- Group: Specify the target group name. You can select the group from the list. x.

- Check Type

- Minimum: Set the minimum clearance between Lead and Hole.

- Maximum: Set the maximum clearance between Lead and Hole.

Figure 2.

- Circle Clearance: Enter the clearance for circular hole.

- Ellipse Clearance: Enter the clearance for ellipse hole.

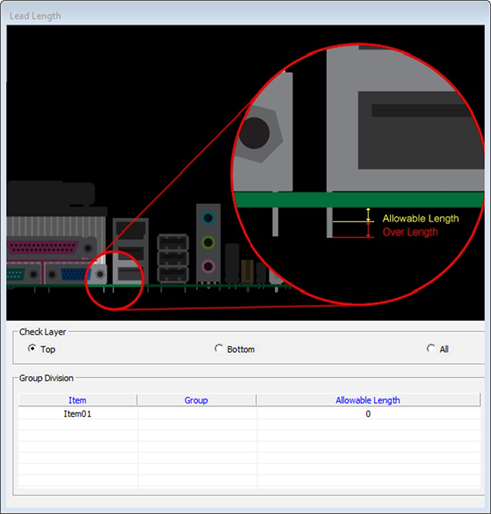

Lead Length

Checks the length of DIP type component’s lead. If it is much longer than the allowable length, PollEx DFA can detect it.

- Check Layer: Select checking target layer.

- Item: Input item name.

- Group: Specify the target group name. You can select the group from the

list.

Figure 4.

- Allowable Length: Input allowable lead length.

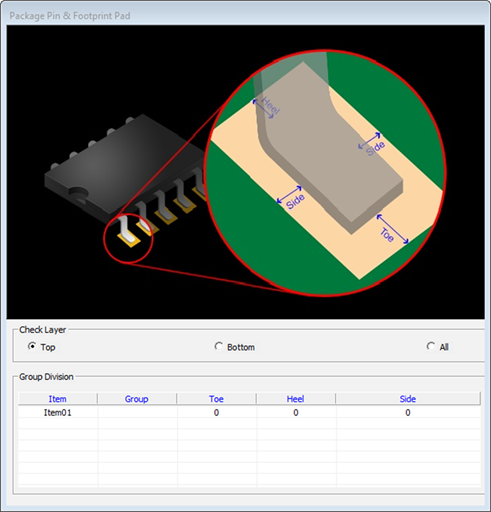

Package Pin & Footprint

Checks the distance between package lead and footprint pad. Inspects toe-print, heel-print, and side distance.

- Check Layer: Select checking target layer.

- Item: Input item name.

- Group: Specify the target group name. You can select the group from the

list.

Figure 6.

- Toe: Distance from package leads edge to footprint pad’s outer edge. If the measured distance is smaller than the given value, it fails.

- Heel: Distance from package leads edge to footprint pad’s inner edge. If the measured distance is smaller than the given value, it fails.

- Side: Distance from package leads edge to footprint pad’s side edge. If the measured distance is smaller than the given value, it fails.