Collision

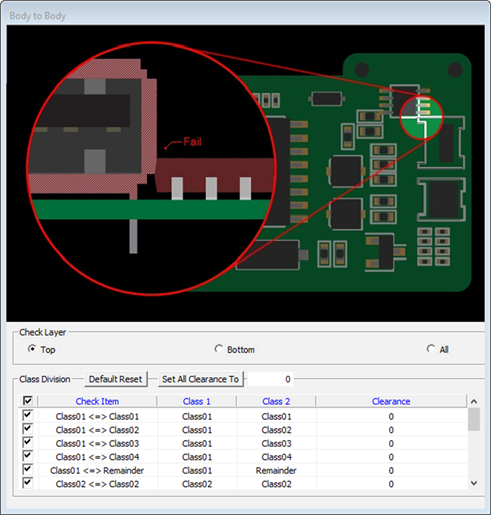

Body to Body

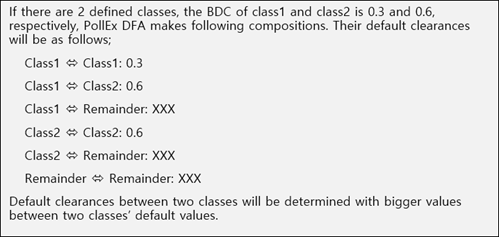

This item checks the clearance between component body and body. The measurement base is 3D package’s body surface to another components’ body surface. Checking is performed for the classes’ compositions which are automatically created by PollEx DFA. Applied clearance values are BDC (Body Default Clearance) values that you input while making each class. You also can change this value.

- Check Layer: Select checking target layer.

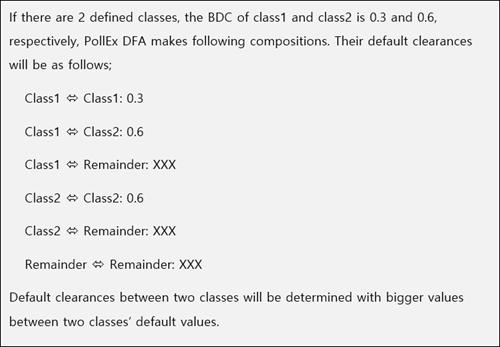

- Default Reset: Automatically create checking components’ class composition based

on each class’s BDC (Body Default Clearance) value.

Figure 2.

- Set All Clearance To: Set all class composition’s BDC values with given values.

- V: Checking item means PollEx DFA checks for it.

- Check Item: Checking item’s name. You can change the name.

- Class1: Checking CLASS name.

- Class2: Checking CLASS name.

- Clearance: Clearance between first and second classes.

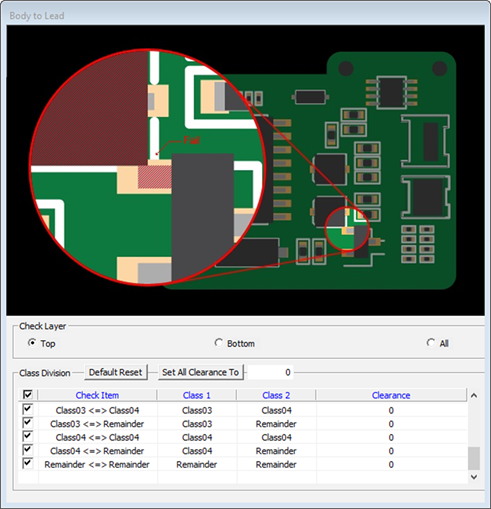

Body to Lead

This item checks the clearance between component body and component leads. Measurement base is 3D package’s body surface to another packages’ lead. Checking is performed for classes’ compositions which are automatically created by PollEx DFA. Applied clearance values are BDC (Body Default Clearance) and LDC (Lead Default Clearance) value that you input while making each class. You also can change this value.

- Check Layer: Select checking target layer.

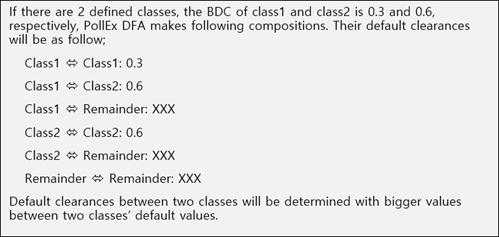

- Default Reset: Automatically create checking components’ class composition based

on each class’s BDC (Body Default Clearance) and LDC (Lead Default

Clearance).

Figure 4.

- Set All Clearance To: Set all class composition’s BDC values with given values.

- V: Checking item means PollEx DFA checks for it.

- Check Item: Checking item’s name. You can change the name.

- Class1: Checking CLASS name.

- Class2: Checking CLASS name.

- Clearance: Clearance between first and second classes.

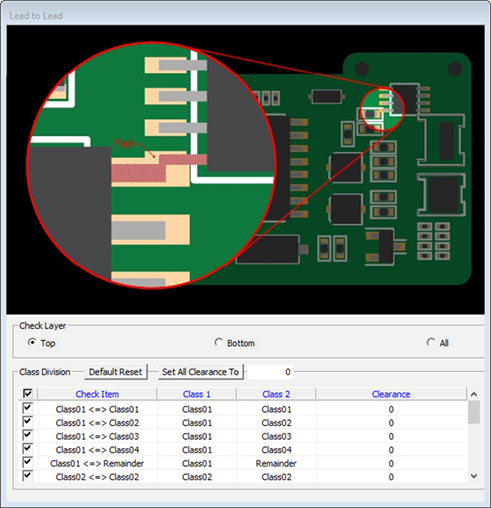

Lead to Lead

This item checks the clearance between component lead and component leads. Measurement base is 3D package’s lead to other packages’ leads. Checking is performed for classes’ compositions which are automatically created by PollEx DFA. Applied clearance values are LDC value that you input while making each class. You also can change this value.

- Check Layer: Select checking target layer.

- Default Reset: Automatically create checking components’ class composition based

on each class’s LDC (Lead Default Clearance).

Figure 6.

- Set All Clearance To: Set all class composition’s BDC values with given values.

- V: Checking item means PollEx DFA checks for it.

- Check Item: Checking item’s name. You can change the name.

- Class1: Checking CLASS name.

- Class2: Checking CLASS name.

- Clearance: Clearance between first and second classes.

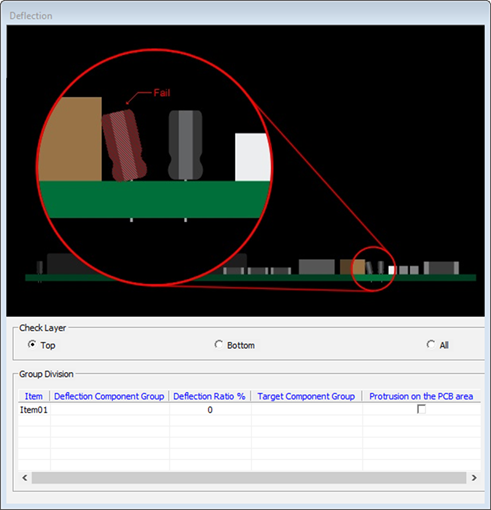

Deflection

- Check Layer: Select checking target layer.

- Item: Input item name.

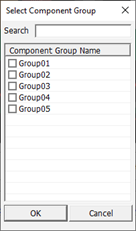

- Deflection Component Group: Specify the target group name. You can select the

group from the list. Double-click the column to open the dialog.

Figure 8.

- Deflection Ratio %: Input the packages deflecting ratio with percent. 90 degree bending case is 100%.

- Target Component Group: Select the target component group to be checked with

deflection component group.

Figure 9.

- Protrusion on the PCB Area: Check the deflected components that are out of PCB area.

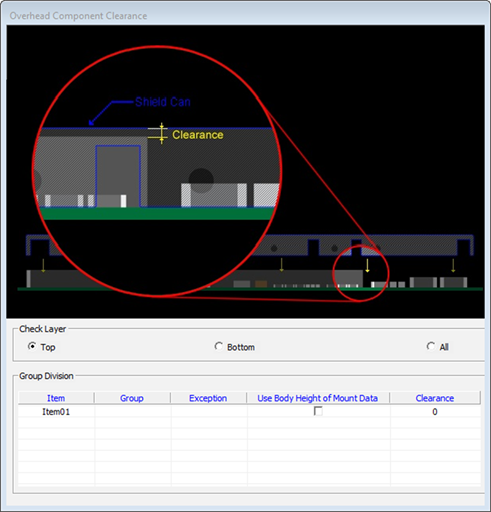

Overhead Component Clearance

Engineers use overhead components such as Shield-Can, Heat-sink and Basket to protect weak components from electro-magnetic. There is an overhead component with covering below the component. If both are too close together, both will be touched. And then, some problems might occur. This item checks the gap between the overhead component and the below component.

- Check Layer: Select checking target layer.

- Item: Input item name.

- Group: Specify the target group name. You can select the group from the list.

Double-click the column to open the dialog.

Figure 11.

- Exception: Define a component group to exclude from checking.

- Use Body Height of Mount Data: Option to check using the values of Body Height that entered in Mount Data of UPF library. When the test result is failed based on the 3D Package geometry, this option allows to re-test by using the Body Height values in the Mount Data. When the re-test result is passed by using the Body Height values even though the failure was caused by the 3D Package geometry, it is determined as Warning.

- Clearance: Input clearance between components and Shield-Can.