HL-T: 1100 Stress Life (S-N) Using Stress History Created from Modal Participation Factors (via a *.pch file) and Modal Stress

Tutorial Level: Beginner

In this tutorial you will:

- Import a model to HyperLife

- Select the SN module with a Modal Superposition loading type and define its required parameters

- Create and assign a material

- Assign a *.pch file (containing modal participation factors) to modal stresses

- Evaluate and view results

Before you begin, copy the file(s) used in this tutorial to your

working directory.

Note: The aim of this tutorial is to:

- Create stress history from modal participation factors and modal

stresses.

For the complete time interval, stress history is given by:

Where,- Stress history for the given time interval of an element

- Participation factor per mode at time t (via mrf/pch file)

- Modal stress of an element per mode (via h3d file)

- Mode

- Perform an SN uniaxial calculation for the above stress history.The above pch file is generated from OptiStruct from a modal transient run.

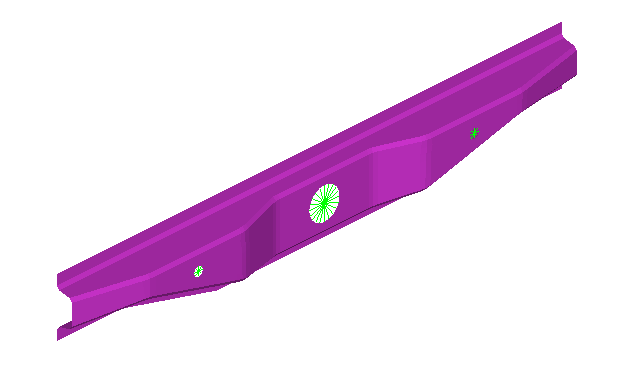

Figure 1.

Import the Model

-

From the Home tools, Files tool group, click the Open Model tool.

Figure 2.

-

From the Load model and result dialog, browse and select

HL-1100\Rear_Truss.h3d for the model

file.

The Load Result field is automatically populated. For this tutorial, the same file is used for both the model and the result.

-

Click Apply.

Figure 3.

Tip: Quickly import the model by dragging and

dropping the .h3d file from

a windows browser into the HyperLife

modeling window.

Define the Fatigue Module

-

Click the SN tool.

The SN tool should be the default fatigue module selected. If it is not, click the arrow next to the fatigue module icon to display a list of available options.

Figure 4.

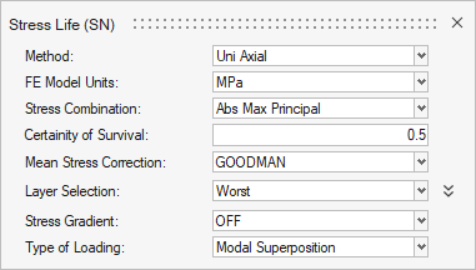

The SN dialog opens. -

Define the SN configuration parameters.

- Select Uni Axial as the method.

- Select MPa for the FE model units.

- Select Abs Max Principal for the stress combination

- Enter a value of 0.5 for the certainty of survival.

- Select GOODMAN for the mean stress connection.

- Select Worst for the layer selection.

- Select Modal Superposition for the type of loading.

Figure 5.

- Exit the dialog.

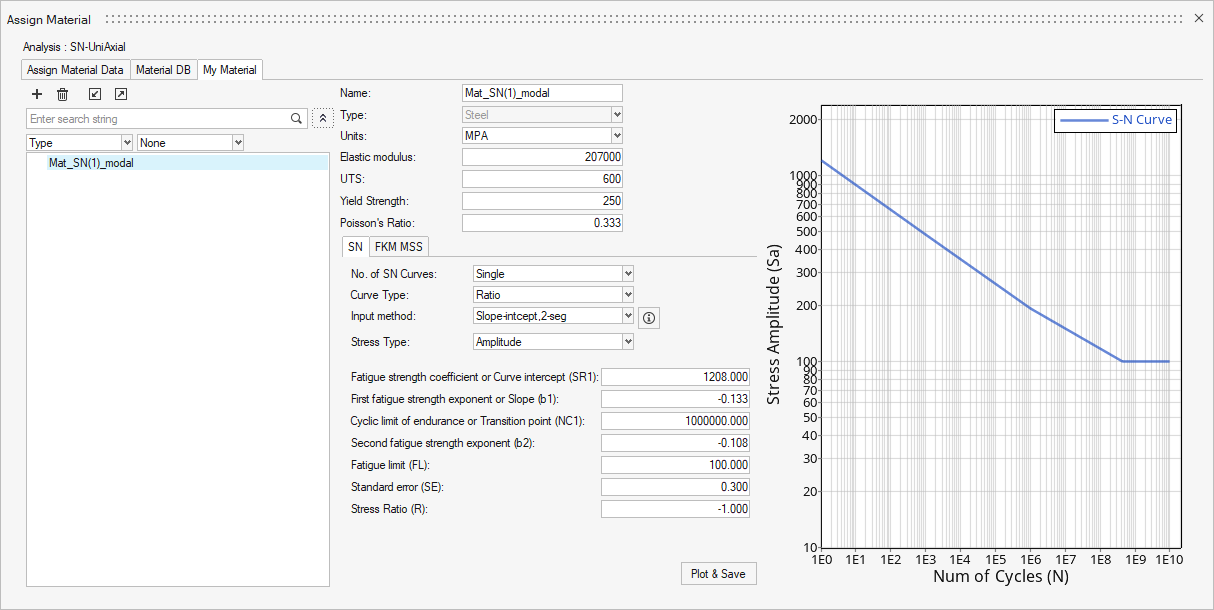

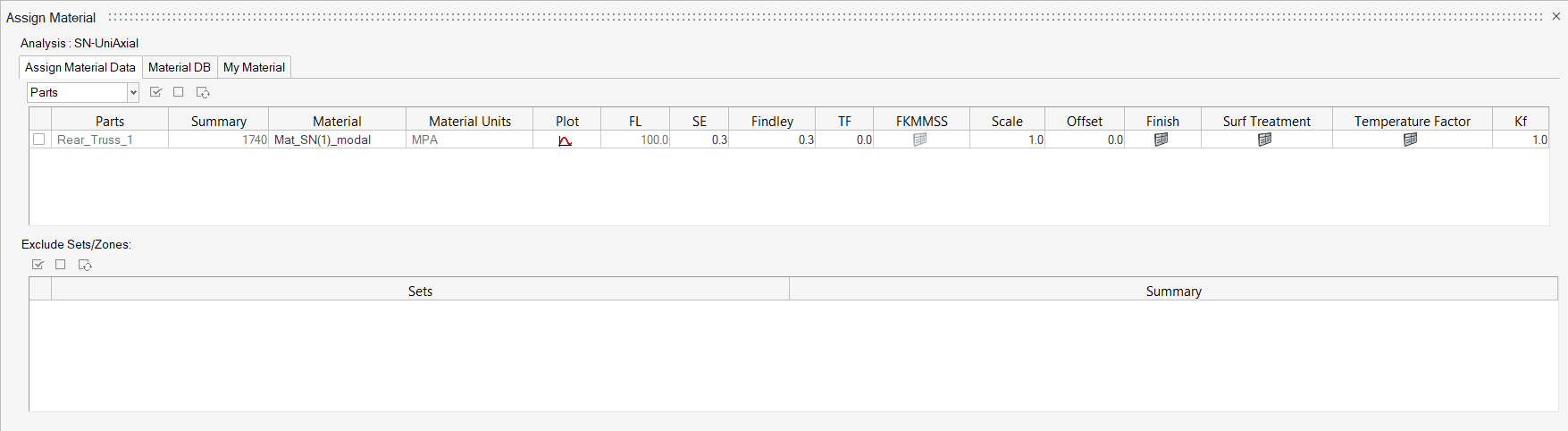

Assign Materials

-

Click the Material tool.

Figure 6.

The Assign Material dialog opens. - Activate the checkbox next to the part Rear_Truss_1.

-

Create a new material.

- Right-click on Mat_SN(1)_modal and select Add to Assign Material List.

-

Return to the Assign Material Data tab and select

Mat_SN(1)_modal from the Material drop-down menu for

Rear_Truss_1.

The Material list is populated with the materials selected from Material Database and My Material.

Figure 8.

- Exit the dialog.

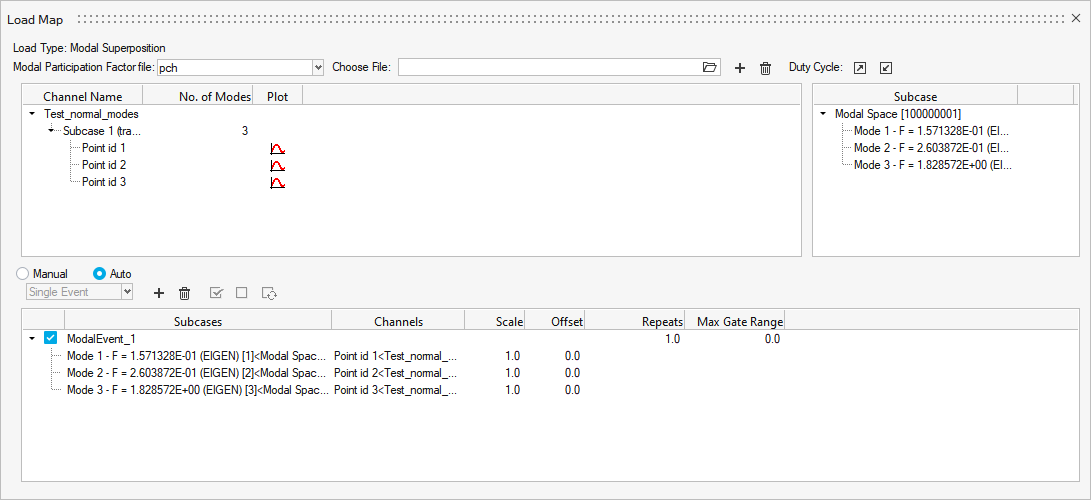

Assign Load Histories

-

Click the Load Map tool.

Figure 9.

The Load Map dialog opens. - From the Channel Type drop-down menu at the top of the dialog, select pch.

-

Click

in the Choose File field and

browse for Rear_Truss_modal.pch.

in the Choose File field and

browse for Rear_Truss_modal.pch.

-

Click

to add the modal participation file.

to add the modal participation file.

- Select Subcase 1(transient) from the loaded pch and Modal Space from the Subcase window, to create an event with all modes.

-

On the bottom half of the dialog, click

.

ModalEvent_1 is created with 1 repeat.

.

ModalEvent_1 is created with 1 repeat. -

Activate the ModalEvent_1 checkbox.

Figure 10.

- Exit the dialog.

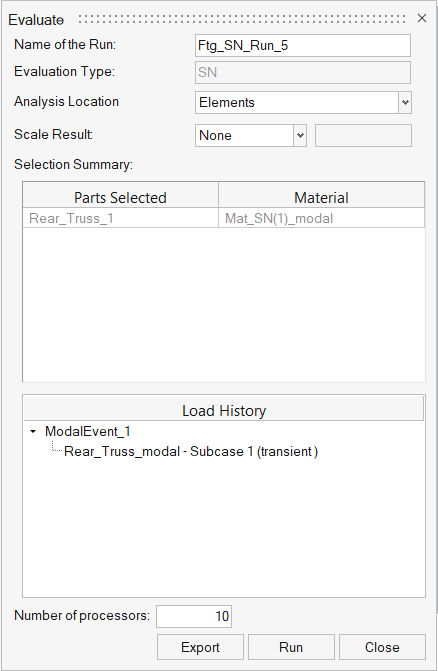

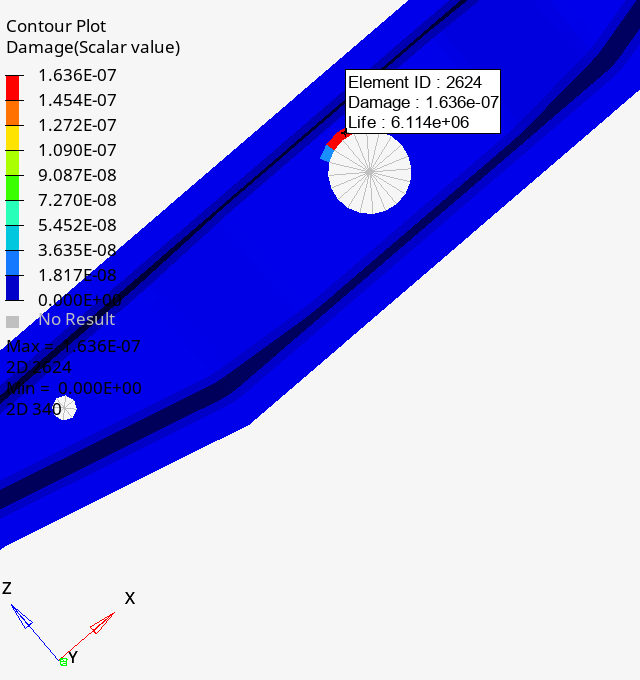

Evaluate and View Results

-

From the Evaluate tool group, click the

Run Analysis tool.

Figure 11.

The Evaluate dialog opens.Figure 12.

- Optional: Enter a name for the run.

-

Click Run.

Result files are saved to the home directory and the Run Status dialog opens.

- Once the run is complete, click View Current Results.

-

Use the Results Explorer to

visualize various types of results.

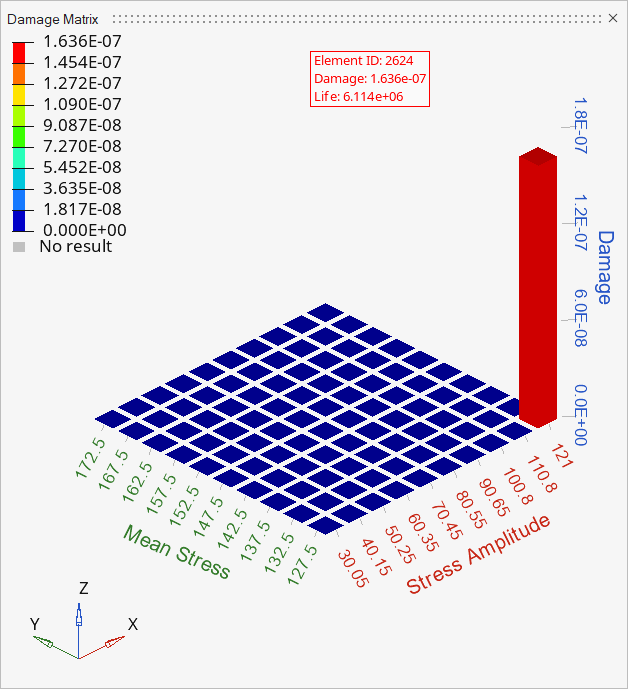

Figure 13.

Figure 14.