Watertight Cabin

Though UFX supports non-manifold and open (not watertight) inputs, having a

watertight cabin will help to avoid any back and forth between modeling and setup.

Once you are comfortable with the model, you can skip certain checks related to

watertightness.

- Extract external surface through a script:

- Stamped parts (parts with continuous thickness – doors, hood, cabin

floor, and so on)

- Script identifies one side of thickness surfaces with maximum area

- After surfaces are extracted, remove unnecessary faces

further such that opposite part boundary edges faces each

other

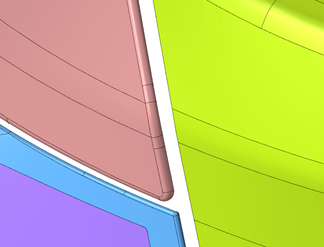

Figure 1.

- Non-stamped parts (mirrors, plastic parts, and so on)

- Manually extract wetted faces

- For some complex parts, you might have to trim some surfaces

in order to extract clean wetted faces

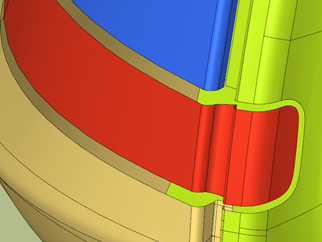

Figure 2.

- Stamped parts (parts with continuous thickness – doors, hood, cabin

floor, and so on)

- Generate facets/mesh on exterior surfaces:

- Generate faceted mesh on extracted wetted faces (use rigid body mesher – maximum size 20 mm, minimum size 0.1 mm, maximum deviation 0.1 mm)

- Rigid body mesher captures all fillets and curvature with optimum number of triads

- Make sure generated facets are not deviating much from geometry

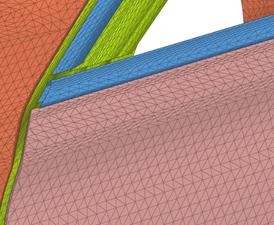

Figure 3.

- Cabin floor parts can be meshed with constant size of 8 mm

- Close holes:

- After facet/mesh generation, fill holes using the Fill Hole/Gap utility

- Select all components

- Define maximum width (generally 50 fills up all holes)

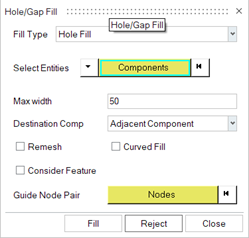

Figure 4.

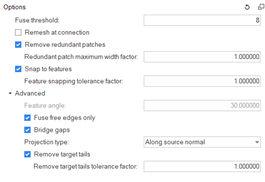

- Fuse gaps:

- Use fuse tool to connect parts with wetted faces

- Upper body parts fuse:

- In the below example, wetted faces are extracted so they have gaps/proximity between them

- The option “Fuse free edges only” is used

- Fuse threshold depends on maximum gap between parts. Generally, it varies between 6-12 mm

- You can select multiple source and target parts for one fuse

operation

Figure 5.

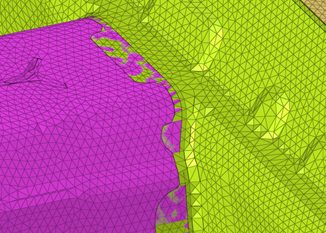

- Fuse cabin floor parts:

- Here parts are either in proximity, overlapping or

intersecting

Figure 6.

- Deactivate the “Fuse free edges only” option for such parts

- Fuse threshold depends on maximum gap between parts. Generally, it varies between 8 - 10 mm

- Source parts will move to target, so select source and target accordingly

- Here parts are either in proximity, overlapping or

intersecting

- After fusing if there are any bad elements, manually fix them at the end

- Generate apron faces for large openings:

- If there is a big gap between cabin floor and upper body, create apron faces first

- Use Fill Hole/Gap tool > Patch fill > Select surrounding nodes and create patch

- Fuse upper body with cabin floor

- Perform checks for watertight cabin:

- Check for free edges, non-manifold edges

- If free edges are valid, mark the corresponding component with “Baffle” name

- Check and fix normal of the cabin