/MAT/LAW48 (ZHAO)

Block Format Keyword This law describes the Zhao material law used to model an elasto-plastic strain rate dependent materials. The law is applicable only for solids and shells.

The global plasticity option for shells (N=0 in shell property keyword) is not available in the actual version.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW48/mat_ID/unit_ID or /MAT/ZHAO/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| A | B | n | Chard | ||||||

| C | D | m | EI | k | |||||

| Fcut | |||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| A | Plasticity yield

stress. (Real) |

|

| B | Plasticity hardening

parameter. (Real) |

|

| n | Plasticity hardening exponent. Default = 1.0 (Real) |

|

| Chard | Plasticity Iso-kinematic hardening factor.

Default = 0.0 (Real) |

|

| Plasticity maximum stress. Default = 1030 (Real) |

||

| C | Relative strain rate

coefficient. Default = 1.0 (Real) |

|

| D | Strain rate plasticity factor. Default = 0.0 (Real) |

|

| m | Relative strain rate exponent. Default = 1.0 (Real) |

|

| EI | Strain rate coefficient. Default = 0.0 (Real) |

|

| k | Strain rate exponent. Default = 1.0 (Real) |

|

| Reference strain

rate. (Real) |

||

| Fcut | Cutoff frequency for strain rate

filtering. Default = 0.0 (Real) |

|

| Failure plastic strain. Default = 1030 (Real) |

||

| Tensile failure strain 1. Default = 1030 (Real) |

||

| Tensile failure strain 2. Default = 1030 (Real) |

Example (Metal)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW48/1/1

metal

# RHO_I

.008

# E nu

200000 .3

# A B n Chard sig_max

145 550 .42 1 0

# C D m E1 k

35 47 .3 185 .3

# eps_rate_0 Fcut

.05 0

# eps_max eps_t1 eps_t2

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The stress-strain function is based

on the formula published by Zhao:Where,

- Plastic strain

- Strain rate

- Except for the strain rate

formulation, the plasticity curve is strictly identical to a Johnson-Cook model:

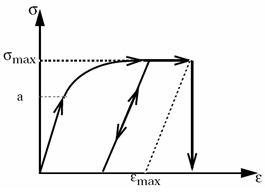

Figure 1.

However, compared to Johnson-Cook, the Zhao law allows a better approximation of a nonlinear strain rate dependent behavior.

- Yield stress should be strictly positive.

- The hardening exponent

n must be less than 1.

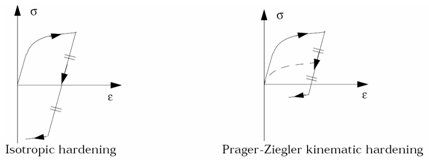

Figure 2.

- The iso-kinematic hardening

parameter is defined as:

- If Chard = 0, hardening is a full isotropic model

- If Chard = 1, hardening uses the kinematic Prager-Ziegler model

- If 0 < Chard < 1, hardening is interpolated between the two models

- If

, the term

, and Equation 1 becomes:

- The strain rate filtering is used to smooth strain rate. It is only available for shell and solid elements.

- When

reaches

in one integration point, then based on the element type:

- Shell elements: The corresponding shell element is deleted.

- Solid elements: The deviatoric stress of the corresponding integral point is permanently set to 0, however, the solid element is not deleted.

- If

(

is the largest principal strain), the stress is reduced

as:

- If , the stress is reduced to 0 (but the element is not deleted).