/FAIL/INIEVO

Block Format Keyword This criterion allows a two-step failure approach, divided into an initiation phase, in which damage has no effect on the stress computation, and a damage evolution phase, in which a stress softening can be generated. Initiation is based on plastic strain as function of several stress state quantities.

When the initiation criterion is reached, stress softening damage variable evolution is triggered. This evolution can be based on a plastic displacement at the time of failure or on a certain value of fracture energy. In addition, the shape can be chosen between a classic linear stress reduction or an exponential drop of the load-carrying capacity. Multiple pairs of initiation/evolution criterion can be combined in the same input card. This criterion is compatible with both solids and shells and can be used with non-local regularization.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/INIEVO/mat_ID/unit_ID | |||||||||

| NINIEVO | ISHEAR | ILEN | FAILIP | PTHICKFAIL | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| INITYPE | EVOTYPE | EVOSHAP | COMPTYP |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| TAB_ID | SR_REF | FSCALE | PARAM | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| TAB_EL | EL_REF | ELSCAL | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DISP | ALPHA | ENER | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits) |

|

| NINIEVO | Number of initiation/evolution

criteria. Default = 1 (Integer) |

|

| ISHEAR | Flag to take transverse shear

components into account (shells only).

(Integer) |

|

| ILEN | Element characteristic length

formulation flag.

(Integer) |

|

| FAILIP | Number of failed integration point

prior to solid element deletion. Default = 1 (Integer) |

|

| PTHICKFAIL | Percentage of failed layers prior

to shell element deletion. 0.0 ≤ PTHICKFAIL ≤ 1.0 Default = 0.0 (Real) |

|

| INITYPE | Damage initiation tabulated

criterion type. 2

(Integer) |

|

| EVOTYPE | Damage evolution type.

(Integer) |

|

| EVOSHAP | Shape of the damage evolution.

(Integer) |

|

| COMPTYP | Criterion combination type (only if

NINIEVO > 0).

(Integer) |

|

| TAB_ID | Failure initiation criterion table

identifier. (Integer) |

|

| SR_REF | Reference strain rate for table

identifier. Default = 1.0 (Real) |

|

| FSCALE | Scale factor for failure initiation

criterion table. Default = 1.0 (Real) |

|

| PARAM | Parameter for failure initiation criterion.

Default = 0.0 (Real) |

|

| TAB_EL | Element size scaling for failure

initiation criterion. (Integer) |

|

| EL_REF | Reference element size for size

scaling table. Default = 1.0 (Real) |

|

| ELSCAL | Scale factor for element size

scaling function. Default = 1.0 (Real) |

|

| DISP | Plastic displacement at

failure. Default = 0.0 (Real) |

|

| ALPHA | Exponential shape parameter (not

applicable for exponential energy- based evolution). Default = 1.0 |

|

| ENER | Fracture energy. Default = 0.0 |

|

| fail_ID | (Optional) Failure criteria

identifier. (Integer, maximum 10 digits) |

Comments

- The

INIEVO failure criterion is a two-step failure

criterion based on plastic strain and stress state. These two steps consist

in the computation of two successive damage variables:

- 1st step: the damage initiation phase, in which an internal variable evolution denoted is computed. This variable is a purely internal value that has no influence on the stress computation. Once this initiation variable reaches the value 1.0, the second stage of the failure is triggered by the computation of the damage variable evolution denoted .

- 2nd step: The damage variable evolution is computed, generating a stress softening effect until the complete failure of the element and its deletion.

- Different types of failure

initiation criterion can be used depending on the INITYPE

parameter value.

- If INITYPE = 1: A tabulated

plastic strain at failure initiation map is given with respect to

stress triaxiality and, optionally, with strain rate.Where,

- Hydrostatic pressure

- von Mises stress

- If INITYPE = 2: A tabulated

plastic strain at failure initiation map is given with respect to a

shear influence variable denoted as and, optionally, with strain rate.Where,

- Pressure influence parameter

- Maximum shear stress

- If INITYPE = 3: A tabulated

modified plastic strain at failure initiation map is given with

respect to principal strain rate ratio and, optionally, with strain

rate. This initiation criterion is also denoted as

MSFLD.

Where, are the principal deviatoric stress component.

- If INITYPE = 4: A tabulated

plastic strain at failure initiation map is given with respect to

principal strain rate ratio and, optionally, with strain rate. This

initiation criterion is also denoted as

FLD.

- If INITYPE = 5: A tabulated

plastic strain at failure initiation map is given with respect to a

stress state parameter denoted as

and, optionally, with strain rate. This initiation criterion is

also denoted as

FLD.Important: The strain rate dependency applied to the failure criterion can only be used with material laws that are strain rate dependent. The strain rate used for the constitutive law (total strain rate, deviatoric strain rate or plastic strain rate), will be the same used for the failure criterion.

- If INITYPE = 1: A tabulated

plastic strain at failure initiation map is given with respect to

stress triaxiality and, optionally, with strain rate.

- The damage initiation

variable,

is computed incrementally

as:

- If INITYPE = 3 (MSFLD), a

modified plastic strain is used, which only evolves when

:

- If INITYPE = 3 (MSFLD) and

INITYPE = 4 (FLD) criteria,

depending on PARAM value, a direct formulation

can be used instead of the incremental one:

- If INITYPE = 3 (MSFLD), a

modified plastic strain is used, which only evolves when

:

- To take into account

regularization of the element size, a table (TAB_EL) can

be defined describing a scale factor for the element size denoted as

map with respect to initial element size

and, optionally, the stress state variable

used in the failure initiation criterion depending on

INITYPE value. For instance, if

INITYPE = 2,

. The element size factor is introduced into

the damage initiation variable computation as:

- When the damage initiation

variable

reaches the value 1, the

damage variable evolution

is triggered, generating a stress softening.

This evolution can be either based on:

- Plastic displacement at failure (DISP), denoted , if EVOTYPE = 1.

- Dissipated fracture energy (ENER) denoted , if EVOTYPE = 2.

- EVOSHAP

parameter allows to define the shape of the damage evolution. For both

evolution type (plastic displacement or fracture energy), a linear and an

exponential shape can be chosen.

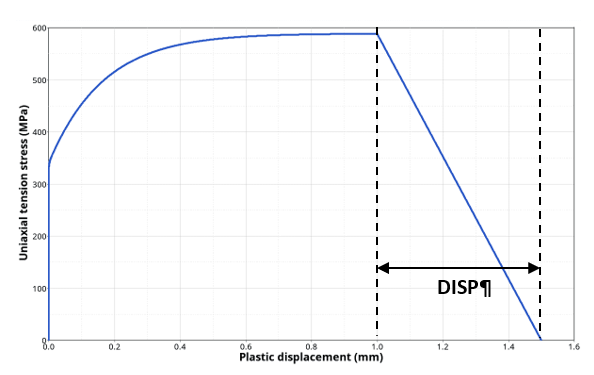

- If EVOSHAP = 1, the damage

evolution is linear:

- If EVOTYPE = 1: plastic

displacement at failure is directly input with

DISP:Where, is the initial element length.

Figure 1. Linear damage evolution with plastic displacement DISP at failure

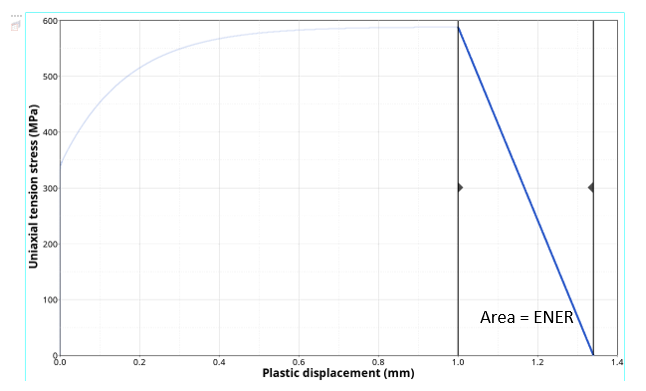

- If EVOTYPE = 2: plastic

displacement at failure is deduced from the fracture energy

input, which is calculated with

ENER:Where, is the yield stress at damage evolution triggering.Note: This expression considers that the plastic behavior is almost perfect at the onset of damage to ensure a dissipated energy equal to .

Figure 2. Linear damage evolution with fracture energy input ENER

- If EVOTYPE = 1: plastic

displacement at failure is directly input with

DISP:

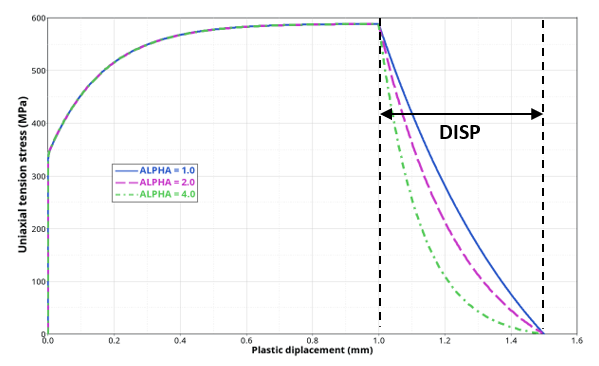

- If EVOSHAP = 2, the damage

evolution is exponential.

- If EVOTYPE = 1: plastic

displacement at failure is directly input with

DISP and shape of the exponential can

be modified with ALPHA.

Figure 3. Exponential damage evolution with plastic displacement DISP. at failure with different alpha parameter value

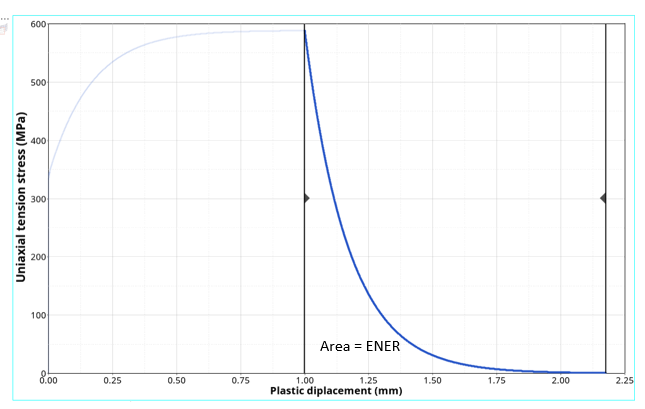

- If EVOTYPE = 2: the area

between the stress – plastic displacement curve of the

exponential function corresponds to the failure energy

ENER.

Figure 4. Exponential damage evolution with fracture energy input ENER

- If EVOTYPE = 1: plastic

displacement at failure is directly input with

DISP and shape of the exponential can

be modified with ALPHA.

- If EVOSHAP = 1, the damage

evolution is linear:

- For the same material,

several pairs of Initiation/Evolution criteria can be defined in the same

input card, setting a value NINIEVO > 1.

In this case, another parameter COMPTYP can be used to

choose the way the different criteria are combined to create the softening effect.

- If COMPTYP = 1: the damage

variable of the criterion concerned, denoted as

, is compared with

the maximum value among all the criteria using

COMPTYP =

1.

Where, is the number of initiation/evolution card using COMPTYP = 1.

- If COMPTYP = 2: the damage

variable of the criterion concerned, denoted as

, is accumulated by a multiplicative

formula among all the criteria using COMPTYP =

2.

Where, is the number of initiation/evolution card using COMPTYP = 2.

Finally, the global damage variable used to calculate the damaged stress tensor is defined as the following maximum value:

Where,- Final damaged stress tensor

- Effective stress tensor (obtained from the material law after plastic return mapping)

- If COMPTYP = 1: the damage

variable of the criterion concerned, denoted as

, is compared with

the maximum value among all the criteria using

COMPTYP =

1.

- FAILIP is an integer value used only for higher order or fully-integrated solid elements. It defines the number of failed integration points before deletion of the solid element.

- The parameter PTHICKFAIL is a real parameter used for shell elements. If PTHICKFAIL is blank or set to 0.0, the value of PTHICKFAIL from the shell property is used. If PTHICKFAIL > 0.0, any PTHICKFAIL value defined in the shell properties are ignored and the value entered in this failure model is used. For values of PTHICKFAIL > 0.0, shell elements fail and are deleted when the ratio of through thickness failed integration points equals or exceeds PTHICKFAIL.

- ILEN

is a flag parameter for you to choose between two possible formulas for

computing the element characteristic length

.

- ILEN=0

- Initial geometrical formulation, where the characteristic length corresponds to the square root of the initial area for shells and the cubic root of initial volume for solids .

- ILEN = 1

- Initial critical timestep formulation where the characteristic length corresponds to the one used to compute the initial element critical timestep. The formula used may vary between the different formulations of shells or solids.

- ILEN = 2

- Current geometrical formulation, where the characteristic length corresponds to the square root of the current area for shells .

- If the non-local regularization is used (/NONLOCAL/MAT), the non-local plastic strain is used to compute the damage initiation variable and the damage variable (and the instability variable if used). Also, in this case, the initial element length in all formula is replaced by the non-local parameter .