Response

Introduction

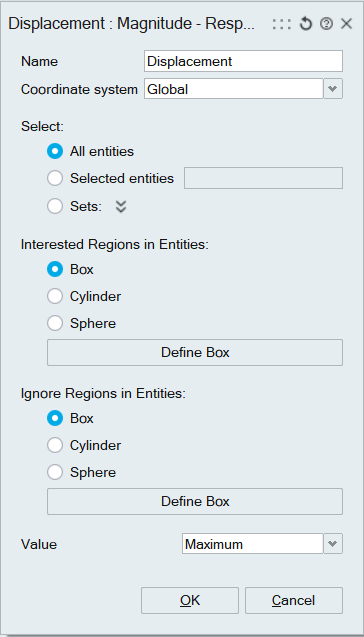

Response is either a result component of solution or component like volume, mass, centre of gravity, and moment of inertia. It is used to query the component in selected entities.

Features

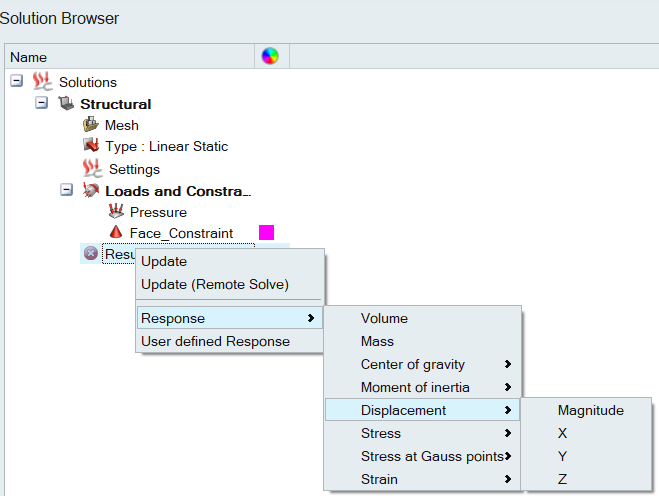

- Right click the results of solution to select the result component.

- Export Responses option is available at right click of Solution name to export the evaluated reponses.

- Only the valid result component will be listed based on the analysis type.

- In case when the result is already available the response value will be updated with the result value. If result is not available, the response will be updated once the result is available.

- Response can be defined for the following inputs,

- Co-ordinate system

- Entities

- Body

- Face

- Edge

- Vertex

- Node

- Element

- Sets

- Regions

- RegionsBox

- Cylinder

- Sphere

- Point

- We can compute the maximum and minimum result value over time / frequency and the

time / frequency where the result is maximum and minimum for transient results. This

option will be shown only for transient and frequency analysis types.

- Plot Graph option is supported in right click options for responses when minimum or maximum value is requested.

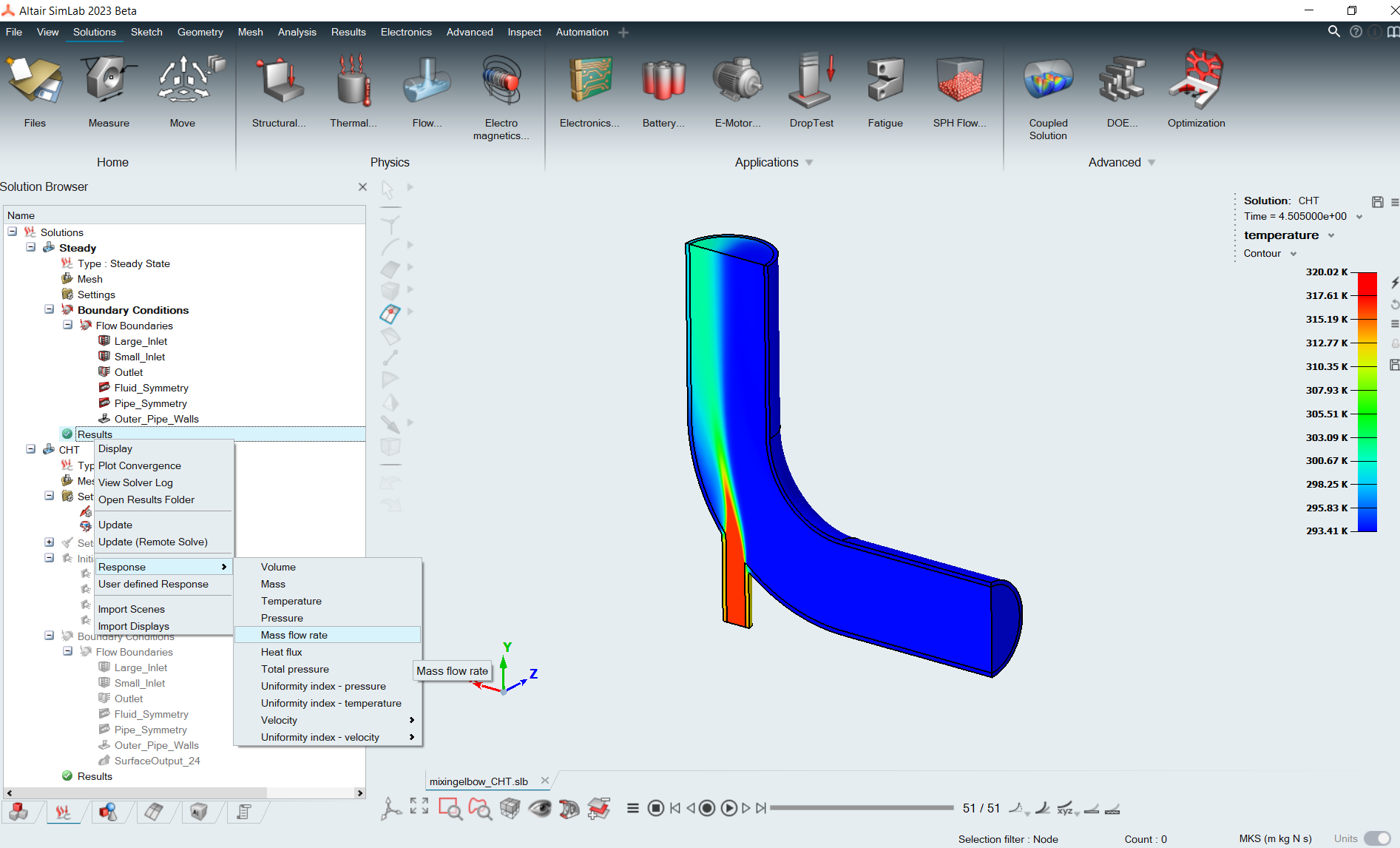

Responses for Flow solution

Response for result components of flow boundaries/surface are supported for steady and transient flow solution.

Result components are:

- Mass flow rate

- Total Heat flow rate

- Total pressure

- Uniformity index – pressure

- Uniformity index –temperature

- Uniformity index – velocity (X, Y, Z)

- For mass flow rate and total heat flow rate, user can either select the faces from GUI or select the flow boundaries/surface outputs.

- If user selects the faces, SimLab computes the total heat flow rate and mass

flow rate by Gaussian surface integration.

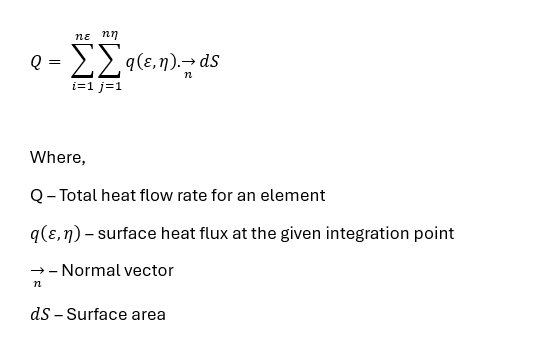

- Heat flow rate is computed by

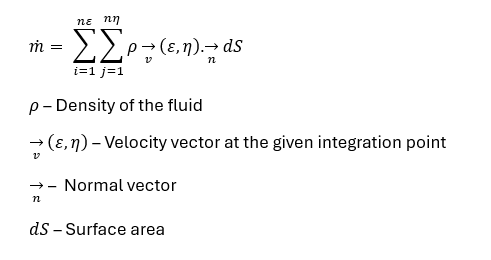

- Mass flow rate is computed by

- Heat flow rate is computed by

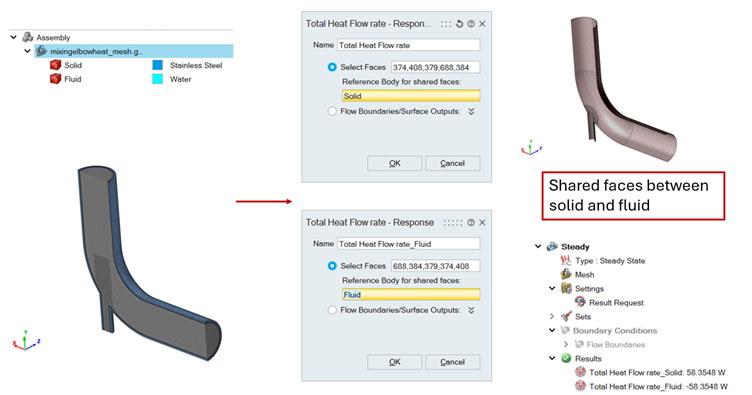

- If user selects the flow boundaries/surface outputs, then acutrans is used to get the output value. If the input surface are shared faces between bodies, then this approach fails to compute the response.

- Alternatively, SimLab-native computation approach can used for shared faces and the reference body can be specified to determine the directional heat flow or mass flow rate with reference to that body.

- If the computed value is negative, the heat/mass flow flows into the reference body.

- Eg: Shown below is water flowing inside the pipe made of stainless steel from two

inlets, small and large inlets with velocity of 1.2 m/s at temperature of 320 K

and 0.4 m/s at 295 K respectively. To see how heat flow flows across the

solid-fluid interface, the total heat flow rate responses is created by selecting

the shared faces along with a reference body.

Responses for electronics thermal solution

Temperature is a significant factor in electronic systems, affecting various components' behaviour. Temperature can influence the electrical characteristics of components and materials, leading to changes in resistance, conductivity, and other properties. Users can create responses for the temperature of one or any number of components to check its trend in the design of experiments.

Responses for electromagnetics solution

Various output parameters in electromagnetic solutions are of interest depending on the specific problem and application. SimLab allows the creation of responses for any of those parameters and DOE enables to analyse these output parameters under various working conditions.

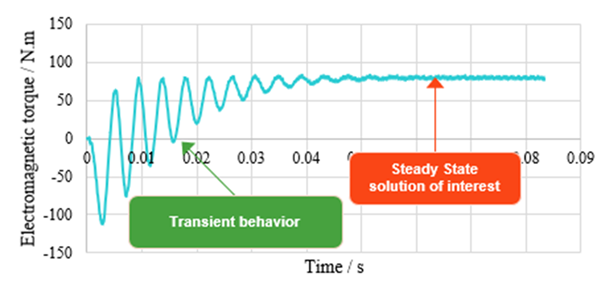

Added a new feature for users to select the interval for computation of Global responses. This has been supported for magnetic transient, magnetostatic and magnetic AC applications. For example, this feature can be useful in transient applications where the system usually takes some time to reach a steady state. However, the system's responses are only of interest once the steady state has been reached. This option can be used to select the specific interval of interest. For magnetostatic and magnetic AC solutions, it is the same concept, but it works only when there is motion.

Creating response for CAD-based solution

- Drop test solution using Radioss solver.

- 2D Electromagnetic solution.

- Electronics thermal solution.