Manage E-Lines

Use the Manage E-Line tool to review and manage E-Lines.

At realization, the finite element entities at each evaluation point will be created. You can also review and edit all E-Lines in bulk in the Review E-Line dialog.

- Realize and Edit E-Lines

- Realize, review, and update interface parameters for one E-Line at a time.

- Review E-Lines

- Use the Review E-Line dialog to review, edit, and update parameters for all E-Lines and to map material compatibility data to squeak lines.

Realize and Edit E-Lines

Review, edit, and update interface parameters for one E-Line at a time.

-

From SnRPre ribbon, Setup group,

select the Manage E-Line tool.

Figure 1.

-

From the guide bar, select an evaluation type:

- All E-Lines

- E-Lines of a specific type (squeak or rattle)

- Unrealized E-Lines

- Manually select an E-Line from the modeling window or use the arrows on the guide bar to review and edit one E-Line at a time.

- Optional:

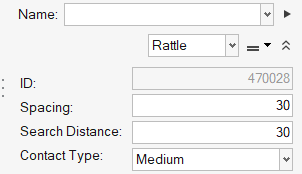

Manually edit or update the parameters if needed.

Figure 2.

-

Complete one of the following options:

- Click

to realize E-Lines and remain in the tool.

to realize E-Lines and remain in the tool. - Click

to realize E-Lines and exit the tool.

to realize E-Lines and exit the tool. - Click

to exit the tool without

realizing E-Lines.

to exit the tool without

realizing E-Lines.

Note: Before proceeding to next step, all E-Lines should be realized and the necessary parameters should be updated.Unrealized E-Line(s) will be realized and, if they are edited, parameters will be updated. FE-entities representing the E-Line will be created. - Click

Review E-Lines

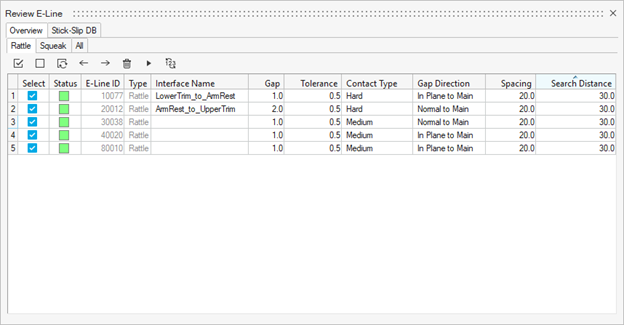

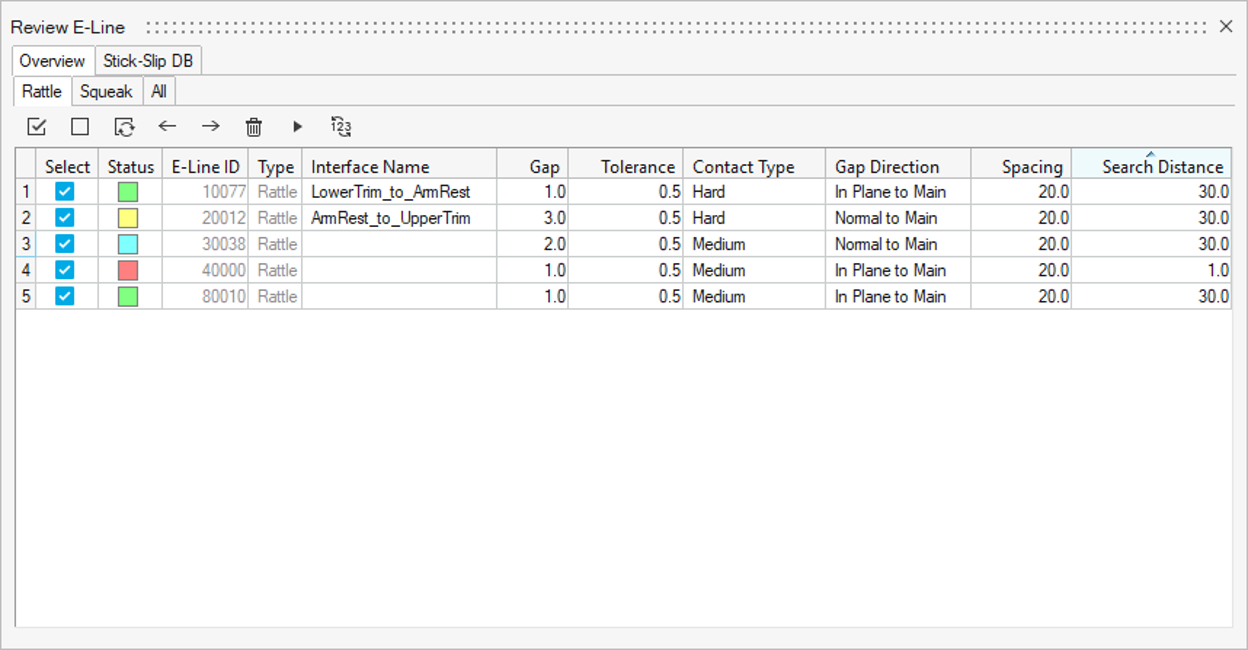

Use the Review E-Line dialog to review, edit, and update parameters for all E-Lines and map material compatibility data to squeak lines. Squeak Evaluation

- View all E-Lines in the model. E-Lines are split by type (Rattle, Squeak, and All) under the sub tabs. Each sub tab exposes only the relevant parameters for the selected type.

- Edit and update E-Line parameters for single or multiple E-Lines (see Manage E-Lines Options).

- Create interface names on the fly, review and update gap and tolerance values for interfaces, or map interface names from an imported DTS file.

- Map materials from Stick-Slip DB to squeak E-Lines.

-

From the SnRPre ribbon, Setup

group, select the Review E-Lines tool

from the Manage E-Lines tool group.

Figure 3.  The Review E-Line dialog opens.

The Review E-Line dialog opens.Figure 4.

-

Click

to delete the selected E-Lines from the model.

to delete the selected E-Lines from the model.

-

Click

to realize the selected E-Lines in the model.

Note: When you edit or update a parameter for a realized E-Line, the line status changes to modified (blue) or unrealized (yellow). For such changes, you will have to realize the updated line. See Manage E-Lines Options for more information.

to realize the selected E-Lines in the model.

Note: When you edit or update a parameter for a realized E-Line, the line status changes to modified (blue) or unrealized (yellow). For such changes, you will have to realize the updated line. See Manage E-Lines Options for more information. -

Click

to renumber the selected E-Lines.

to renumber the selected E-Lines.

- Specify an interval.

-

Click

to renumber the selected

E-Lines.

to renumber the selected

E-Lines.

-

Click

to close the renumbering

workflow.

to close the renumbering

workflow.

Note: The last four digits of an ID cannot be edited and will be set and controlled automatically. The smallest E-Line ID is 10000.

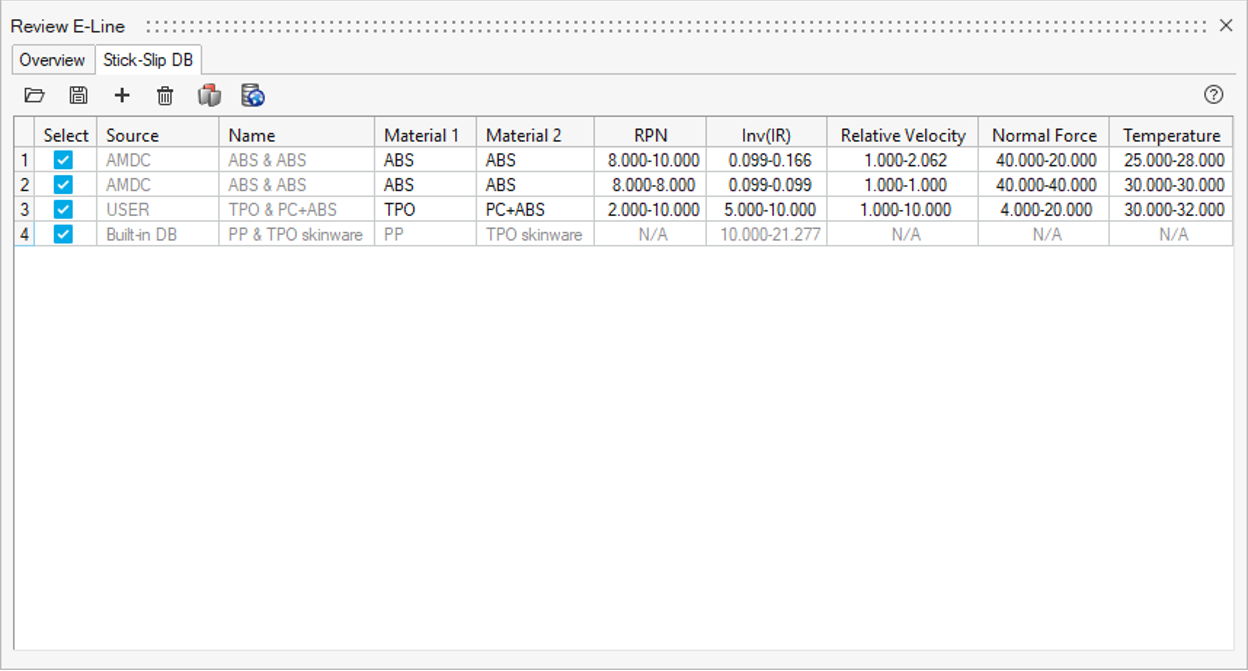

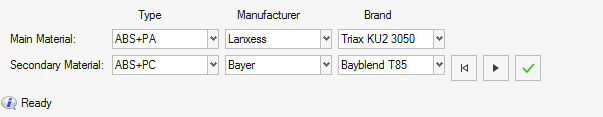

Stick-Slip DB

Stick-Slip testing provides compatibility information for material pairs and supports squeak assessment in post-processing of E-Lines (Squeak Evaluation).

The idea behind mapping materials from Stick-Slip DB is to incorporate testing data without interfering with the materials of the FE model.

- Extract all material compatibility information from Stick-Slip DB on AMDC.

- Use the built-in DB from Squeak and Rattle Director to get (impulse rate)-1 values.

- Input data from in-house testing.

-

From the SnRPre ribbon, Setup

group, select the Review E-Lines tool

from the Manage E-Lines tool group.

Figure 5.  The Review E-Line dialog opens.

The Review E-Line dialog opens. -

Select the Stick-Slip DB tab.

Figure 6.

-

Click

to open an existing Stick-Slip

DB file.

to open an existing Stick-Slip

DB file.

-

Click

to export a

.csv file once created.

to export a

.csv file once created.

-

Click

to add material pairs from

Stick-Slip DB on AMDC.

Learn more in Stick-Slip DB on AMDC.

to add material pairs from

Stick-Slip DB on AMDC.

Learn more in Stick-Slip DB on AMDC. -

Click

to add

material pairs from built-in DB on Squeak and Rattle Director.

to add

material pairs from built-in DB on Squeak and Rattle Director.

-

Click

to add material pairs from

in-house testing.

Note: Only Material 1/Material 2 names and Inv(IR) are mandatory for further assessment. Other information is for awareness only and can be left blank if not available.

to add material pairs from

in-house testing.

Note: Only Material 1/Material 2 names and Inv(IR) are mandatory for further assessment. Other information is for awareness only and can be left blank if not available. -

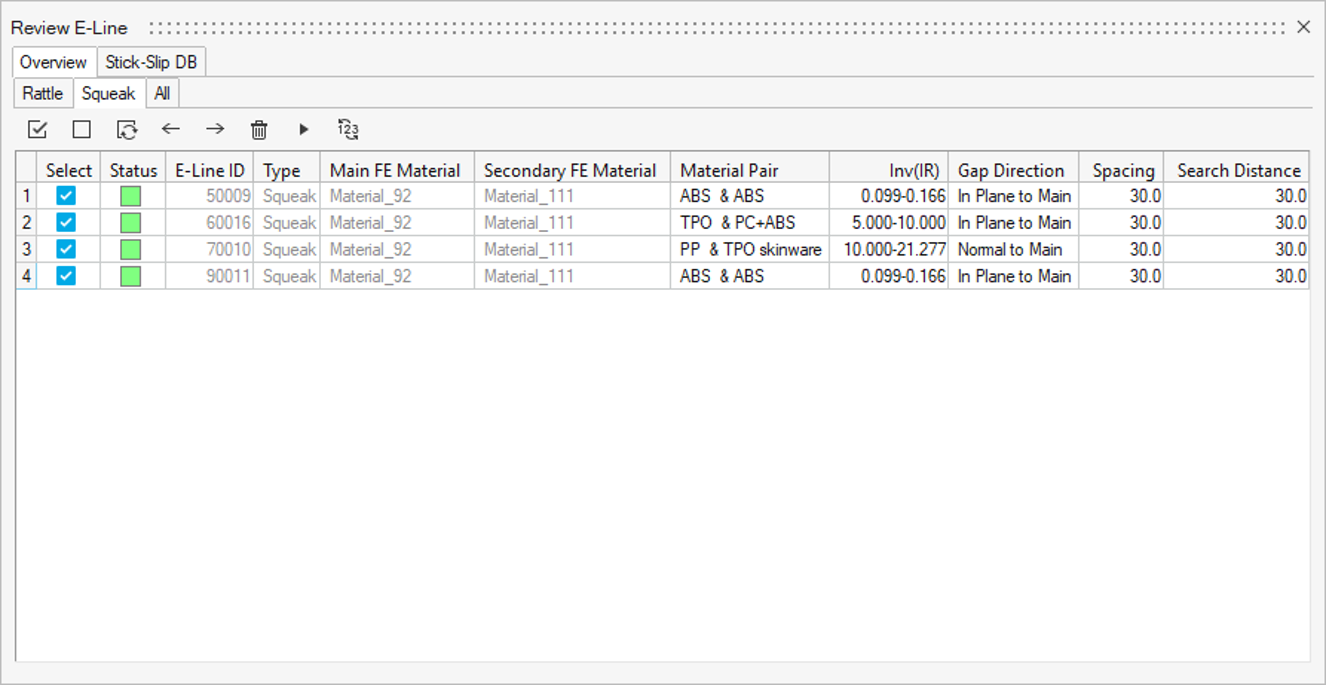

Return to the Overview tab and map the material pairs to the squeak E-Line under the Material Pair column.

Figure 8.

Manage E-Lines Options

The following options are available in the Review E-Line dialog.

- Status

- Contains the E-Lines realization status

- E-Lines ID

- A unique ID for each E-Line along with the number of connections for respective E-Lines (last digits).

- Type

- Defines what type of phenomena to evaluate along the line – rattle or squeak.

- Interface Name

- Enter a name or assign from imported DTS file (if used) to respective E-Line in model to map the GD&T data.

- Gap

- Gap value for the interface in the specified gap direction. This is defined based on the Gap assignment method.

- Tolerance

- Design tolerance for gap in the specified gap direction. This is defined based on the Gap Assignment method.

- (Impulse Rate)⁻¹ range

- Inverse of Impulse Rate range is a measure of the material pair compatibility. This is defined based on the material mapping and only applies to Squeak lines.

- Contact Type

- Define Contact type for the E-line. This is based on Youngs' modulus value of the Main and Secondary FE material.

- Gap Direction

- Realization Projection direction that controls creation of the local coordinate systems which determines the Gap direction.

- Spacing

- Value for the spacing between two adjacent Evaluation Points on an E-Line.

- Search Distance

- Value for search / gap tolerance between the selected Main-Secondary component.

- Main FE Material

- Assigned FE material for main component in the E-Line.

- Secondary FE Material

- Assigned FE material for secondary component in the E-Line.

- Material Pair

- Mapped Material Pair from Stick-Slip DB to the E-Line.

: realized

: realized  : unrealized

: unrealized  : modified

: modified  : failed

: failed