Altair MotionSolve 2023.1 Release Notes

Altair Multibody Solutions 2023.1 Release Notes

Highlights

The Altair Multibody Solutions 2023.1 release includes the following enhancements and

bug fixes to MotionView and MotionSolve:

- Run settings enhancements (MotionView)

- New FMU export with parameters (MotionView)

- Deformable Curve, Deformable Surface contact (MotionSolve )

- Frequency response analysis (MotionSolve)

- Tire test rig analysis in the Entity Browser (MotionView)

- Tire code version up (MotionSolve)

- Removal of Create button to define vehicle events (MotionView)

New Features

- Run Settings Enhancements

- The following improvements to the Run settings, aimed at optimizing the

user experience, are outlined below:

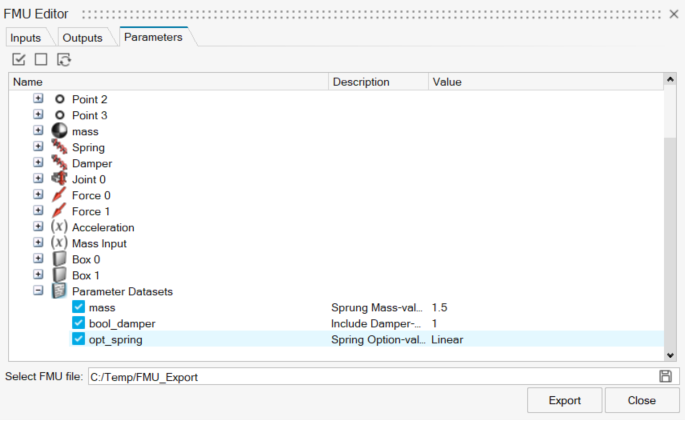

- The Run Defaults menu, accessible from , features the following options:

- Choose Offline as the default solver mode (classic). This turns off the live animation feature, creates a solver input file instead, and calls the solver in a command-line interface.

- Instruct MotionView to create a folder with the Run name in the working directory. The solver input, log, and output files are stored in this folder instead.

- Instruct MotionView to print the Python-based API commands for MotionSolve in a file during a live run execution.

- Select the preferred MotionSolve input file format for

offline runs. You can choose between XML (classic) or

Python (new python-based API).

Figure 1.

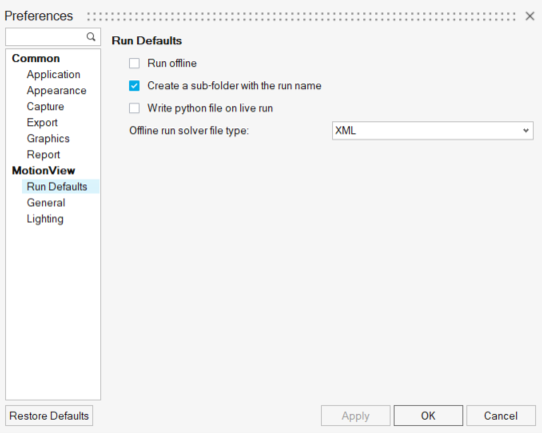

- Enhancing the Run settings with options to either run a current

active analysis or select an analysis from a list of available

analyses.

Figure 2.

- The Run Defaults menu, accessible from , features the following options:

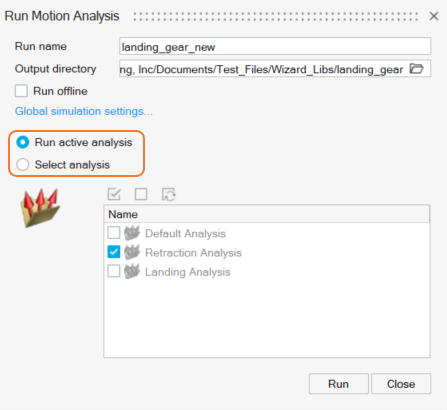

- FMU Export with Parameters

- The MotionSolve FMU (Functional Mock-up Unit) export from MotionView has

been revamped. The updated process provides the option to select

modeling attributes as parameters for the FMU. With this feature, the

FMU can be made designable aiding the inclusion of the FMU in design

variation studies. The FMU can be exported using FMU Editor, accessible

from .

Figure 3. - Deformable Curve, Deformable Surface Contact

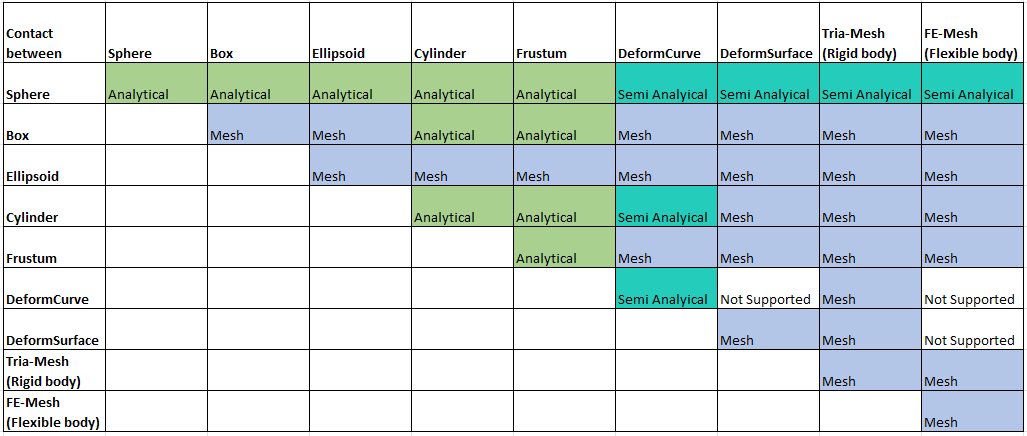

- MotionSolve supports new contact between Deformable Curve and Deformable

Surface to other geometries. The supported combinations for contacts are

described below:

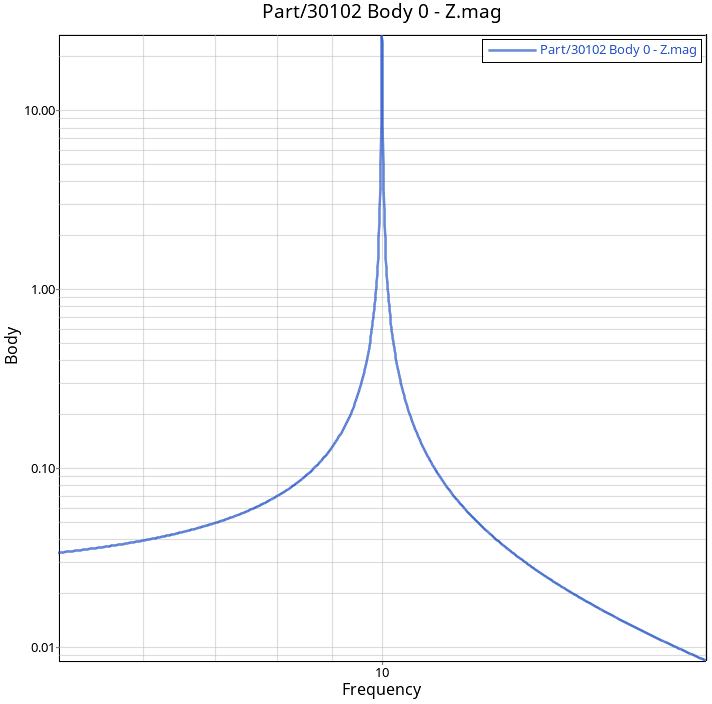

Figure 5. - Frequency Response Analysis

- MotionSolve introduces FrequencyResponse as a new analysis capability,

designed specifically for conducting frequency response analysis. This

analysis is defined by Reference_FrequencyInput,

which includes both magnitude and phase angle. You can specify the

system excitation on any marker, utilizing forces, displacements,

velocity, and acceleration as the basis. The frequency response analysis

yields comprehensive results, encompassing output requests of various

types such as Marker_Displacement, Marker_Velocity, Marker_Acceleration,

and Marker_Force. This ensures a thorough exploration of the system's

behavior under different frequencies of excitation, providing valuable

insight into its vibration characteristics and dynamic response. This

analysis helps identify critical frequencies that may lead to resonance

or other undesirable effects.

Figure 6. - Design of Experiments Using msolve API

- MotionSolve's Python-based API has been extended with a DOE package for design space exploration. Multiple experiment design types are supported, ranging from factorial to randomized and user-defined designs. You can specify design parameters and response variables for your model. On run, various simulation cases are created and scattered throughout the design space, and then executed either sequentially or in parallel. The output of the DOE can be post-processed either directly in Python, or imported into Altair HyperStudy. The DOE package allows you to navigate the complex landscape of design choices, enabling you to make informed decisions and create optimized and innovative solutions.

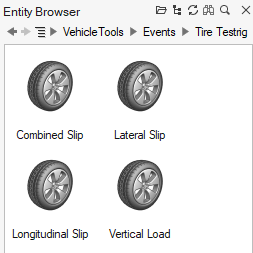

- Tire Test Rig Analysis in the Entity Browser

- The list of analyses available for the tire test rig is now included in

the Entity Browser under . Use the Entity Editor to modify the analysis parameters.

Figure 7. - Siemens MF-Tyre/MF-Swift Version up to 2306

- MF-Tyre/MF-Swift from Siemens distributed with Altair HyperWorks is updated to Simcenter Tire version 2306.

- Cosin FTire Version up to 2023-2

- MotionSolve now supports the updated version of Cosin F-Tire 2023-2 used in vehicle simulations.

Enhancements

- Virtual Joints

- MotionView supports the MotionSolve feature to virtualize constraints, such as Joints and Motions.

- Flexbody Mode Selections

- The Set statement for flexbody mode selection, *SetFlexbodyModes(), has been enhanced with the keyword ALL to indicate the selection of all modes.

- New Units Support

- MotionView now covers all units currently supported by MotionSolve. The

following units are supported:

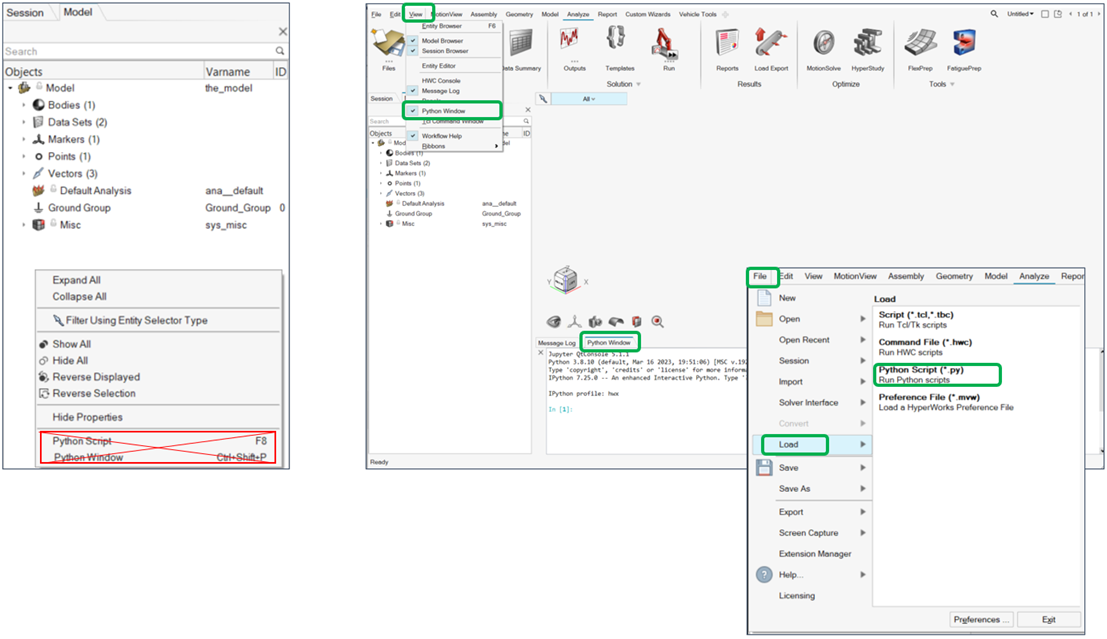

FORCE LENGTH MASS TIME CENTINEWTON NANOMETER TONNE MICROSECOND MILLINEWTON ANGSTROM MICROGRAM NANOSECOND MICRONEWTON YARD NANOGRAM DAY MEGANEWTON MILLIINCH MEGATONNE POUNDAL MICROINCH KILOTONNE NANONEWTON MILS MICROMETER - Python Console

- Access to the Python Script and Python Window is no longer available

through the Model Browser context menu. To access Python Window, use the

View menu. Access Python Script with .

Figure 8. - Additional Attributes in H3DOutput

- MotionSolve supports two additional attributes, linz_animation and frf_animation, to turn on/off the new linear animation results _linz.h3d and frequency response results _frf.h3d.

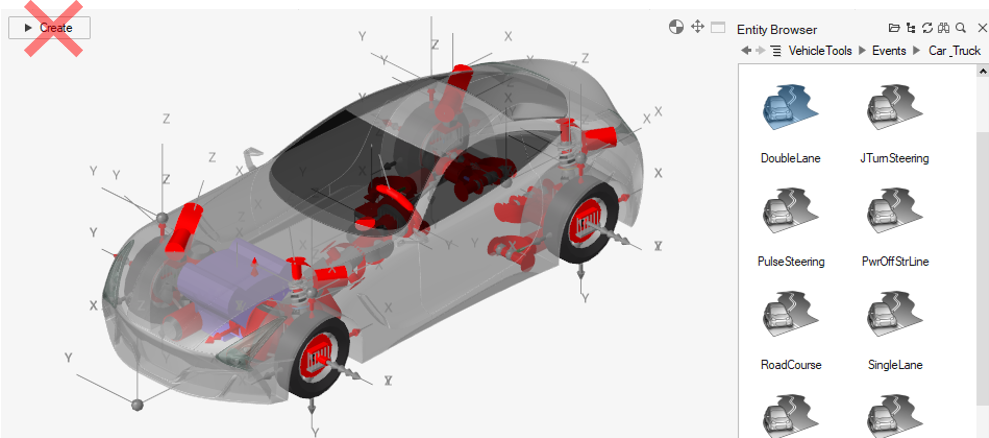

- Removed Create Option to Define Vehicle Events

- In the previous release, when adding a vehicle event from the Entity

Browser, it was required to confirm the selection and click

Create to add the event. Now, double-click

the event icon in the Entity Browser to add the event to the model

automatically.

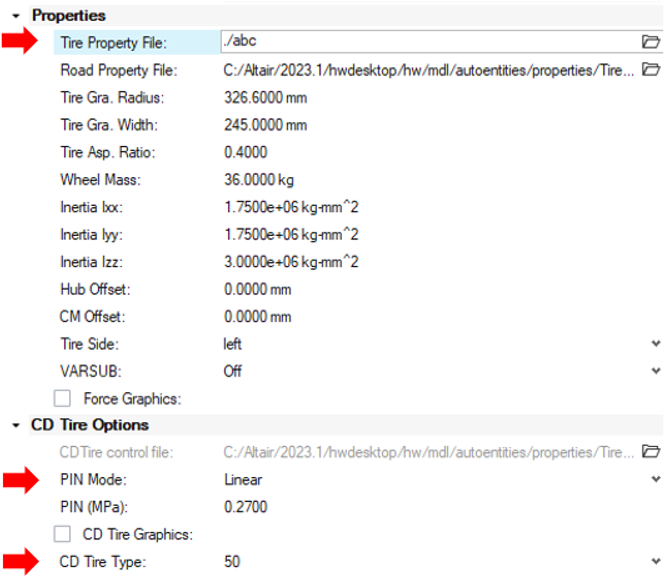

Figure 9. - CDTire File Extension

- The CDTire file extension contains information used in the simulation,

such as tire type and tire pressure (tire_50.21 means type 50 and

pressure 0.21Mpa). You can obtain this information from the tire

property file, however, the Tire entity in MotionView only accepted the

CDTire property file containing type and pressure in the file

extension.

Figure 10. - Enhanced MotionSolve Log Message for MF-Tire/MF-swift ROAD_SOURCE Removal

- When updating MF-Tyre/MF-Swift version from 2020.2 to 2212, Siemens deprecated the ROAD_SOURCE attribute in the tire property file. Simulation models with old tire property files, when solved with the newer distribution, failed with an error; making it necessary to remove the line from the tire file to perform the simulation.

Resolved Issues

- ID is not displayed for rigid groups in the browser.

- Python subroutine with relative a path fails in run offline.

- Unable to export archive of iterations from Review section of the Optimization Wizard.

- Workflow help for Outputs of type Expression or User-Defined is not correct.

- Model with kinematic outputs on bodies does not solve with live run.

- Erroneous move of flexbodies, which has a body coordinate system defined using Euler angles.

- Entity Browser returns to the root folder when switching views.

- Live run generates application error for stability event with the option Use vehicle states in linear.

- DxDyDz field in the Entity Editor goes missing for Marker/Bushing after using options on the screen in Orientation context.

- Live run does not apply initial conditions on joints.

- Unresolved attachment causes partial listing of Attachments in the Entity Editor.

- Valid Scope option in Advanced selection dialog invoked from the Entity Editor does not work.

- Data set members with NO_EDIT set appear editable in Data Summary.

- Default run directory under Global Simulation Settings cannot be changed.

- Application error encountered when closing a Table Form dialog.

- The Kinetic energy distribution for bodies having inertia across products now shows negative values in distribution.

- MotionSolve can now support an OptiStruct connection directly with a flexible body without the need for a dummy body.

- Plane graphics with offset was not displayed in the right position in post-processing.

- Assembly analysis is not forced in some sequential simulations, which was causing linear analysis to fail.

- MotionSolve application error when wrong units are specified in Param_Unit.

- Obstacles with materials defined differently from the road surface or as a rigid are now supported for tracked vehicles on soft soil.

- A wrong unit input in a control block in the ESP FMU was interfering with the ABS signal for some specific vehicle maneuvers.

- Distance versus Velocity curve input included in the Altair Drive File (.adf), using non-SI units, was not converted properly in the MotionSolve simulation.

- MotionView models containing the Aerodynamics file (.aae) was not exporting the file to the solver when using a relative file path.

- Vehicle models using the Altair Fiala tire with cam contact consumed a large amount of RAM memory based on the number of cams. The issue was causing a long initialization time and a slow simulation.

- Brake in turn events for a car model failed with a final velocity below 2km/h.

- Using signal inputs without a file header in the nPost event was causing a solver crash.

- A unit conversion issue in the engine inertia of the vehicle library models with “IC Engine Friction Clutch (Manual)” was fixed. Consequently, the Engine Inertia value in the must now be added in the model units (default kgmm2) instead of kgm2.

Known Issues

- The live animation run option in MotionView currently does not support vehicle models with CDTire.

- Graphics displayed in AirSpring and F-Tire (Cosin Tire Graphics option selected) remain static during the live animation run option in MotionView. For models containing these graphics, it is recommended to visualize the animation using HyperView.