RequirementsForSimulationTool

Requirements for Simulation Tools

![]()

Library

Modelica/Mechanics/Rotational/UsersGuide

Description

This library is designed in a fully object oriented way in order thatcomponents can be connected together in every meaningful combination(e.g., direct connection of two springs or two inertias).As a consequence, most models lead to a system ofdifferential-algebraic equations (DAE) of index 3 (= constraintequations have to be differentiated twice in order to arrive ata state space representation) and the Modelica translator orthe simulator has to cope with this system representation.According to our present knowledge, this requires that theModelica translator is able to symbolically differentiate equations(otherwise it is e.g., not possible to provide consistent initialconditions; even if consistent initial conditions are present, mostnumerical DAE integrators can cope at most with index 2 DAEs).

The elements of this library can be connected together in anarbitrary way. However, difficulties may occur, if the elements which can lock therelative motion between two flanges are connected rigidlytogether such that essentially the same relative motion can be locked.The reason isthat the cut-torque in the locked phase is not uniquely defined if theelements are locked at the same time instant (i.e., there does not exist aunique solution) and some simulation systems may not beable to handle this situation, since this leads to a singularity duringsimulation. Currently, this type of problem can occur with theCoulomb friction elements such asBearingFriction, Clutch, Brake or LossyGearwhen the elements become stuck:

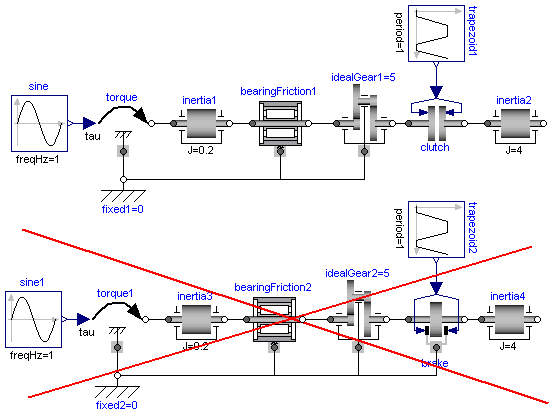

In the figure above, two typical situations are shown: In the upper part ofthe figure, the series connection of rigidly attached bearingFriction1 andclutch components are shown. This does not hurt, because the bearingFriction1element can lock the relative motion between the element and the housing (fixed1),whereas the clutch element can lock the relative motion between the twoconnected flanges. On the contrary, the drive train in the lower part of the figuremay give rise to simulation problems, because the bearingFriction2 elementand the brake element can lock the relative motion between a flange andthe housing and these flanges are rigidly connected together, i.e.,essentially the same relative motion can be locked. These difficultiesmay be solved by either introducing a compliance between these flangesor by combining the bearing friction and brake element intoone component and resolving the ambiguity of the frictional torque in thestuck mode of that component. A tool may handle this situation also automatically,by picking one solution of the infinitely many, e.g., the one wherethe difference to the value of the previous time instant is as smallas possible.