Global Parameters

Analysis Parameters

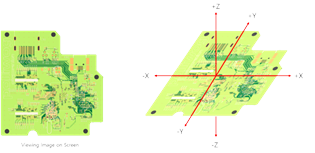

Gravity direction: Using the direction of gravity, you can set the board placement status. Define the actual board’s using status. Many of thermal diffusions are flow through board. But also, the convection on board or on component is not ignored. At this calculation, the direction of board has direct relation with air flows.

Figure 1.

Ambient temperature(C): Thermal diffusion with convection (at natural convection) could be get with the following formula:

Q= ha(Tw -Tf)

Tw: High temperature.

Tf: Lower temperature.

It means that board level convection Tf value of ΔT(Tw-Tf) (temperature difference) may be ambient temperature.

In general case, thermal diffusion on board can be classified into three types of method, conduction, convection, and radiation. Among these methods, radiation is most effective thermal diffusion ways. Many of cases, heat transfer is not done just by one type of methods. It the mediator is fluid, heat transfer is done by directly moving molecules. Currently, we call vertical heat transfer with convection and horizontal heat transfer, advection. Heat transfer in component body, we call them conduction which heat transfer by vibration of solid molecule.

Default comp analysis power level(%): PollEx Thermal use the power values of UPF file. Assuming UPF files’ power level as maximum power value, specified default ratio of maximum power will be used during analysis for component applied power. (default is 80%)

Convection boundary condition type: If there are forced convection conditions, users can define the forced convection type. Normal convection condition is natural convection.

Flow direction of forced convection: If the convection type is Forced convection case, this value is valid. Set the forced flow direction among –X, +X, -Y and +Y.

Inlet flow velocity of force convection (m/s): If the convection type is Forced convection case, this value is valid. Set the flow strength with the speed value.

Comp/board glue material: Define the material to attach components on board. To use material for this value, users need register material into library. PollEx Thermal use the heat transfer coefficient value of material.

Thermal pad material: Define the material of thermal pad. To use material for this value, users need register material into library. PollEx Thermal use the heat transfer coefficient value of material.

Joule heating/IR-drop model: Choose and apply the joule heating or IR-drop model for PollEx Thermal analysis. You can use the external model.

Convection Flow Material Properties

- Flow material name

- Thermal Conductivity (W/m.K) [default: -1]

- Mass density (Kg/m^3) [default: -1]

- Specific heat (J/Kg.K) [default: -1]

- Viscosity (N.s/m^2) [default: -1]