Defining VTS Data, Billet Taper, and HTC

Use the Process Data tool to define the variable time step (VTS) data, billet taper, and heat transfer coefficient.

Defining the Variable Time Step Automatically

- Ram speed

- Ram acceleration time

- Upset billet length

- Butt length

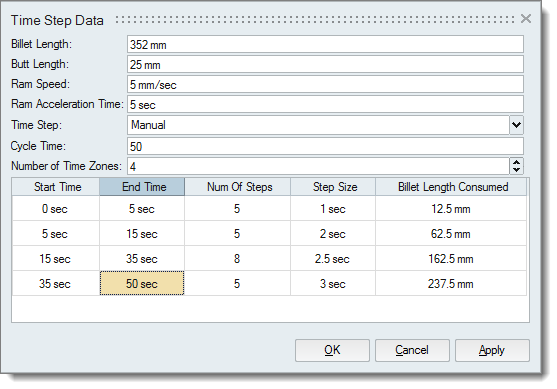

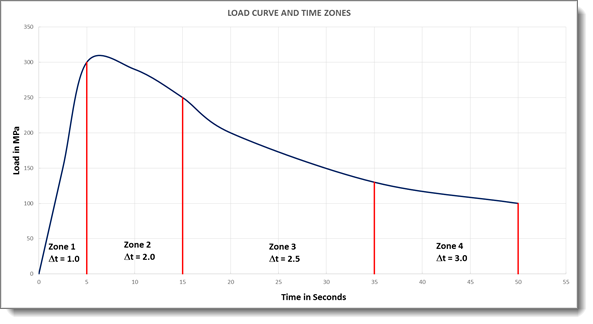

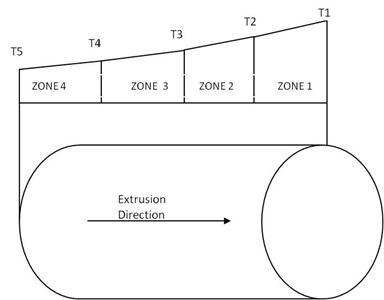

Defining the Variable Time Step Manually

The Manual option in the Time Step Data dialog is used to control and change the time step for a transient problem. This allows you to define up to five different time step sizes during the cycle (referred to as zones).

Inspire Extrude automatically estimates the cycle time. You can reduce this cycle time to solve for less than full cycle analysis.

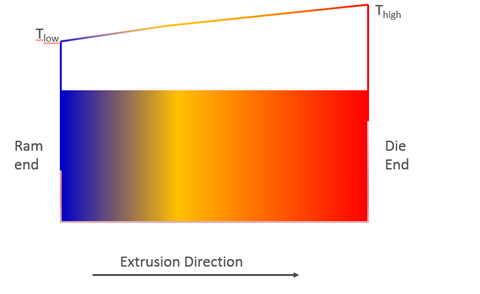

Setting Up the Billet Taper

- Axial taper

- Lateral taper

- Radial taper

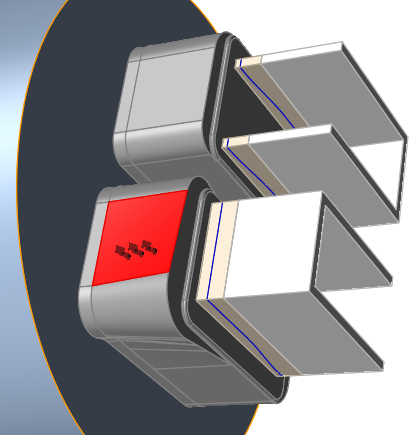

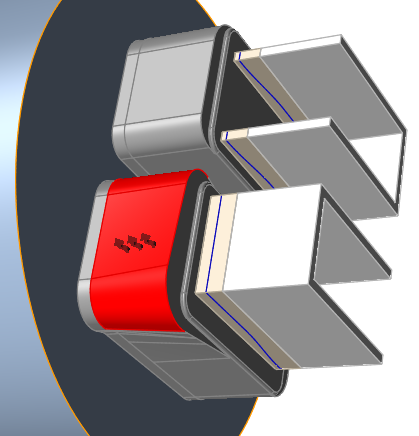

Billet Taper Examples

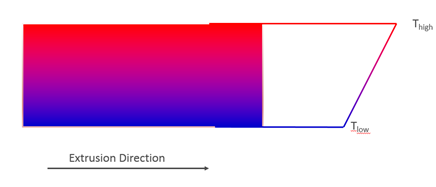

Lateral Taper

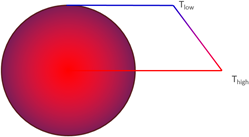

Radial Taper

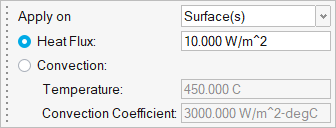

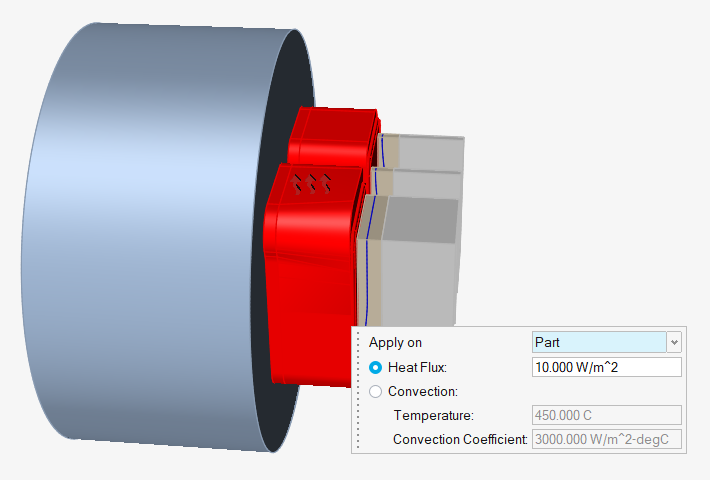

Defining Heat Transfer Coefficient

Select faces to specify heat transfer boundary conditions.