OS-SL-T: 1030 Preloaded Modal Frequency Response Analysis

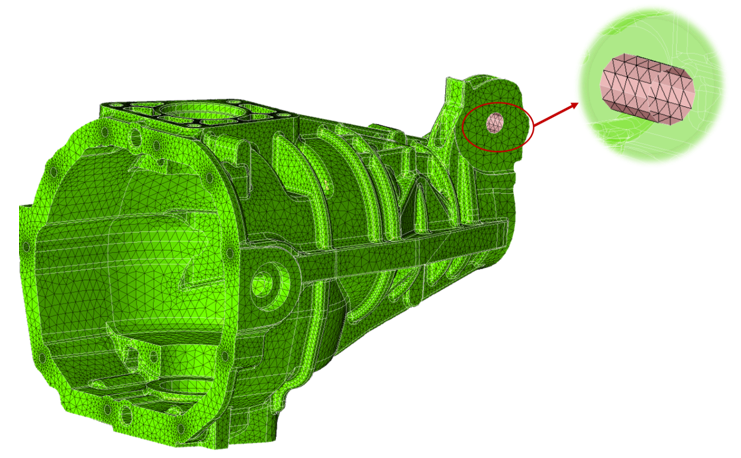

This tutorial demonstrates how to solve a modal frequency response analysis for a Differential housing model by including the effect of pretension of bolts as preload.

- Set up the problem in SimLab

- Apply Loads and Boundary Conditions

- Solve the job

- View the results

- Plot graph

Launch SimLab

Import the Model

Set Up Problem

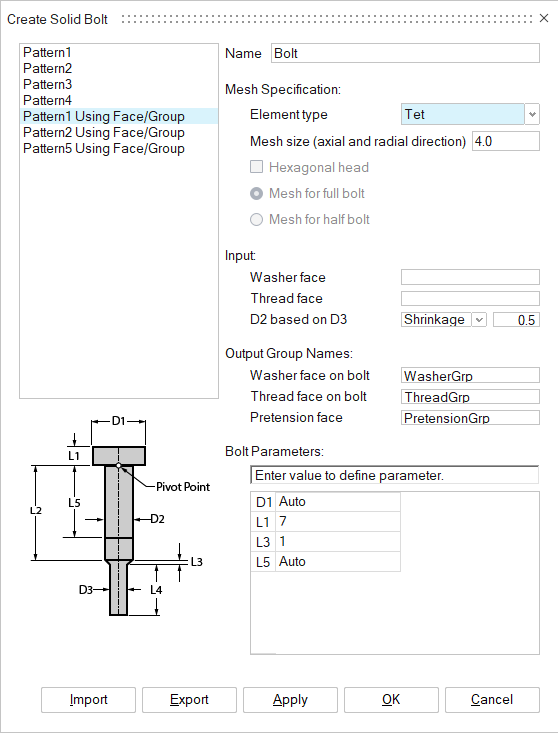

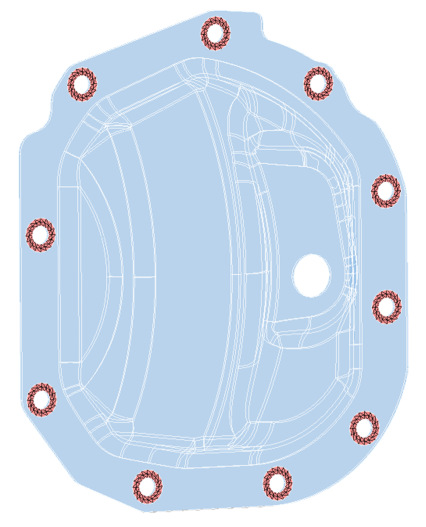

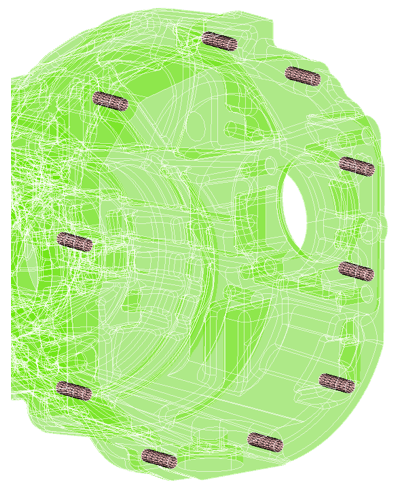

Create Solid Bolds for Assembly

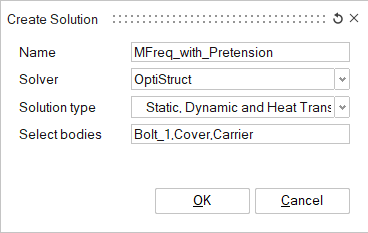

Create Solution

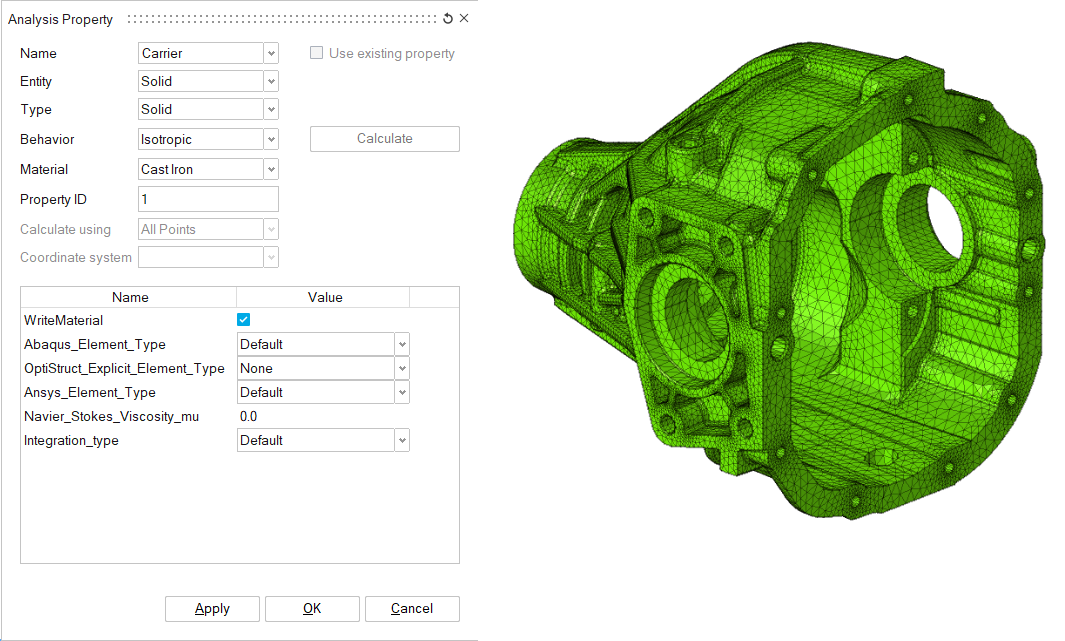

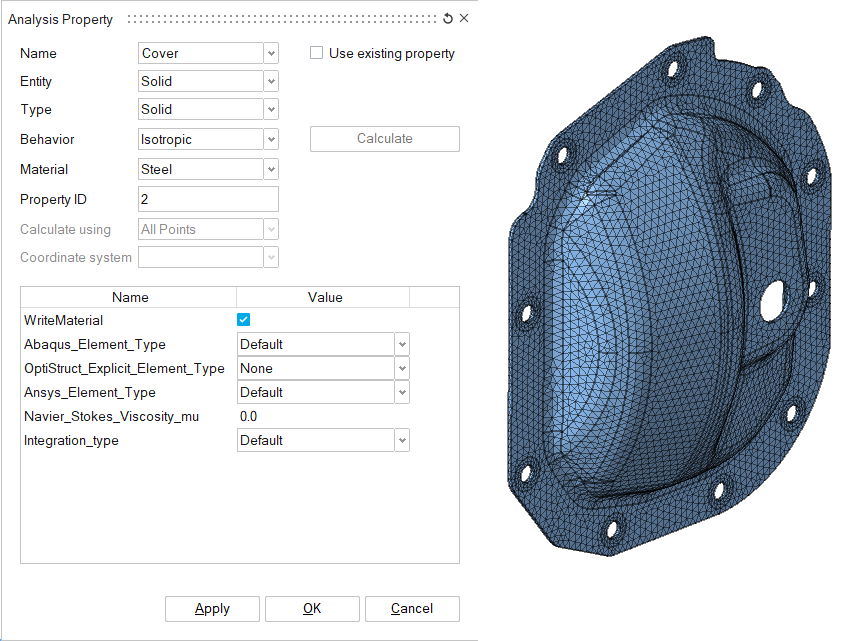

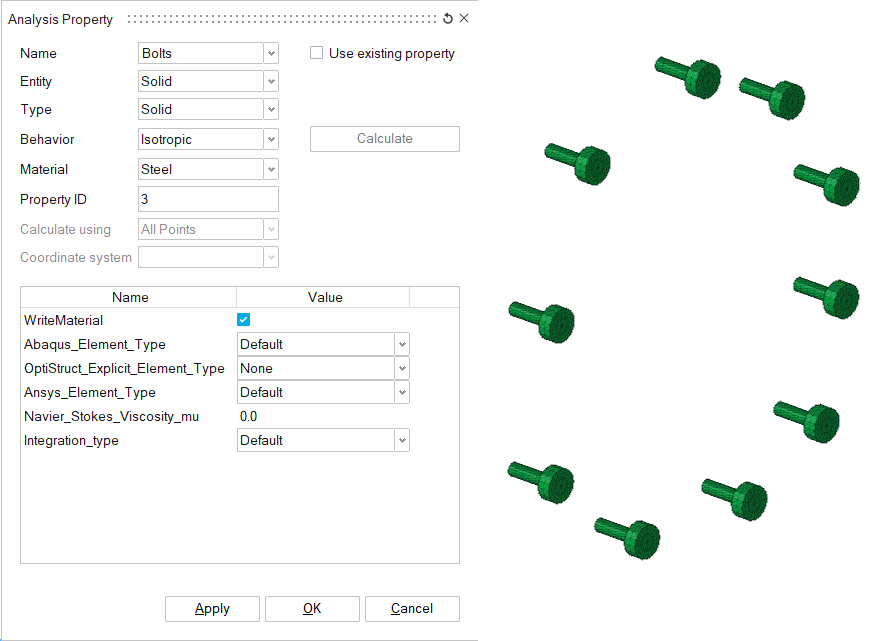

Assign Property to Bodies

In this step you will assign the Cast Iron property for both the Carrier and Cover bodies and Steel property for the Bolts.

SimLab has default materials defined, so there is no need to define materials.

Apply Loads and Boundary Conditions

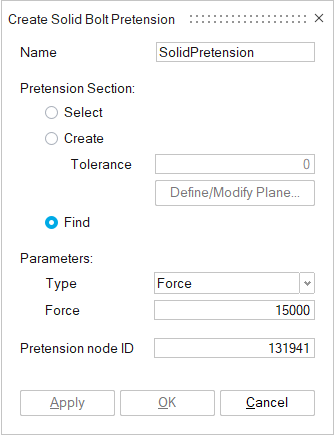

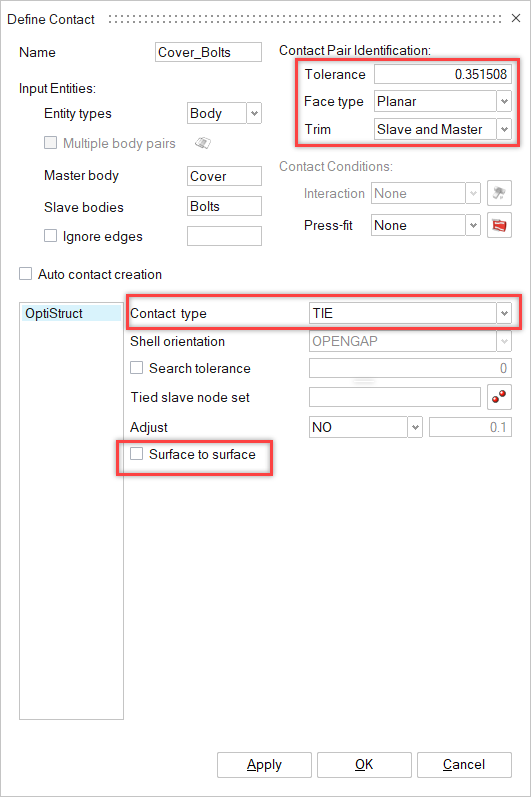

The first loadcase is the non-linear static analysis where pretension is applied on the bolts and constraints are defined on the end of the carrier body. The second loadcase is the modal frequency response analysis in which a pressure load is applied on the inner face of the cover body and excitation load is created using the pressure load. The pretension effect of the bolts in the first loadcase is included in the second loadcase. Contacts are created between each part of the model.

Create Loadcase

Create Pretension Load

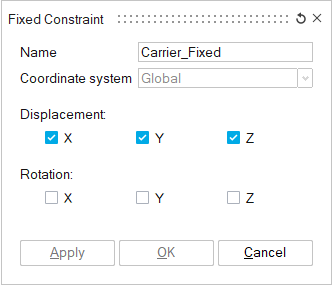

Create Constraints

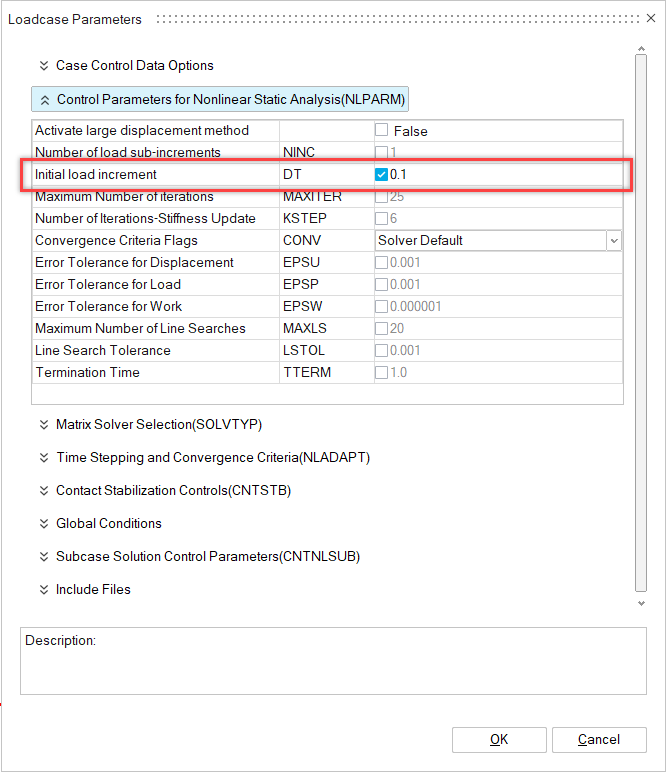

Define Loadcase Parameters

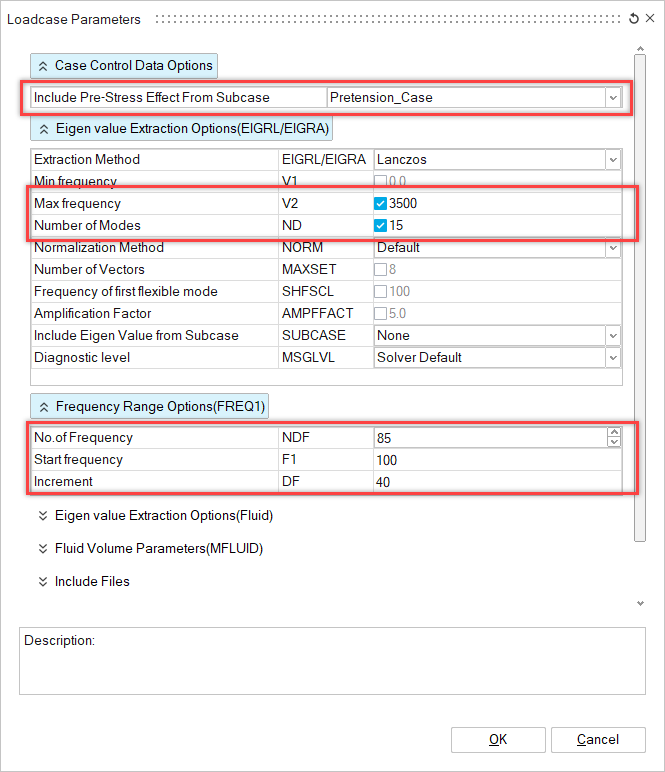

Define Frequency Response Analysis Loadcase

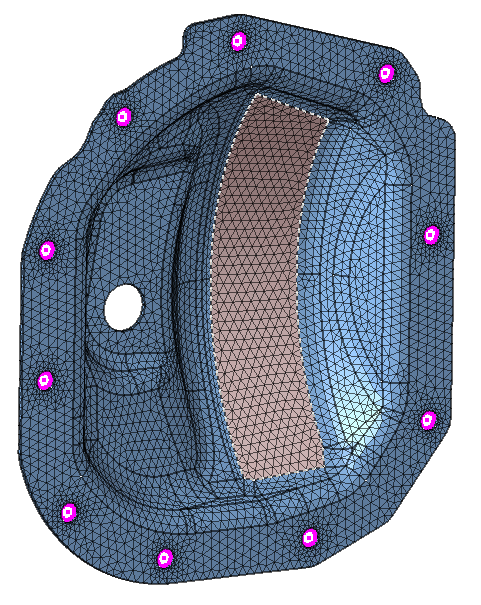

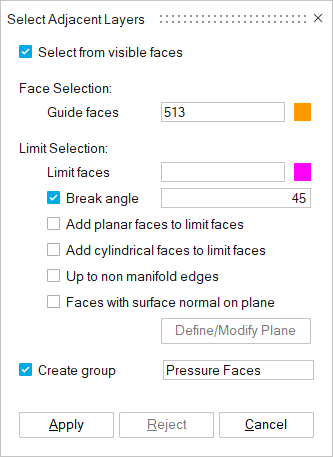

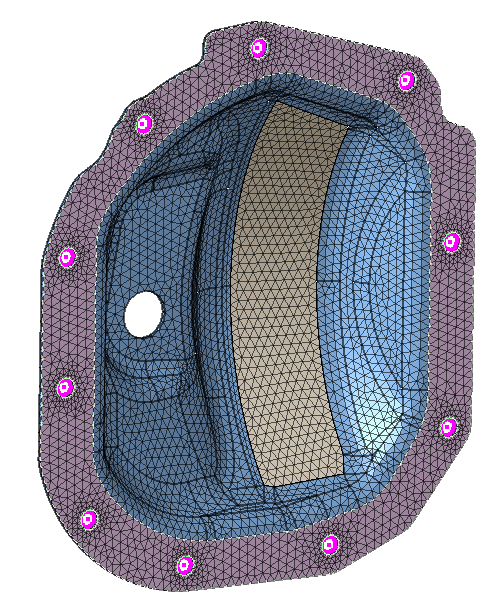

Create Face Group for Pressure Load

Multiple faces must be selected to create a pressure load on the inner face of the cover body.

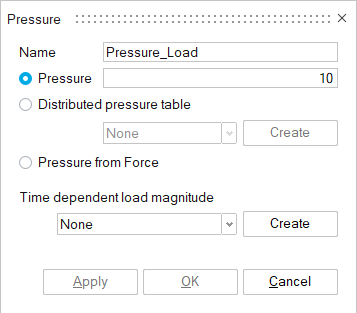

Create Pressure Load

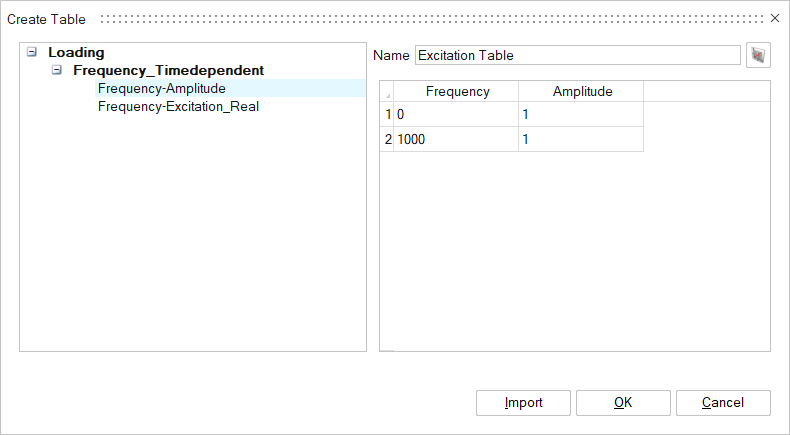

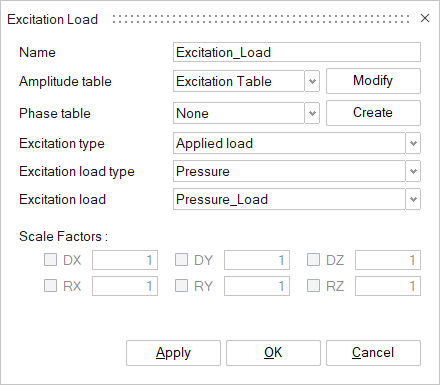

Create Excitation Load

Add Fixed Constraint

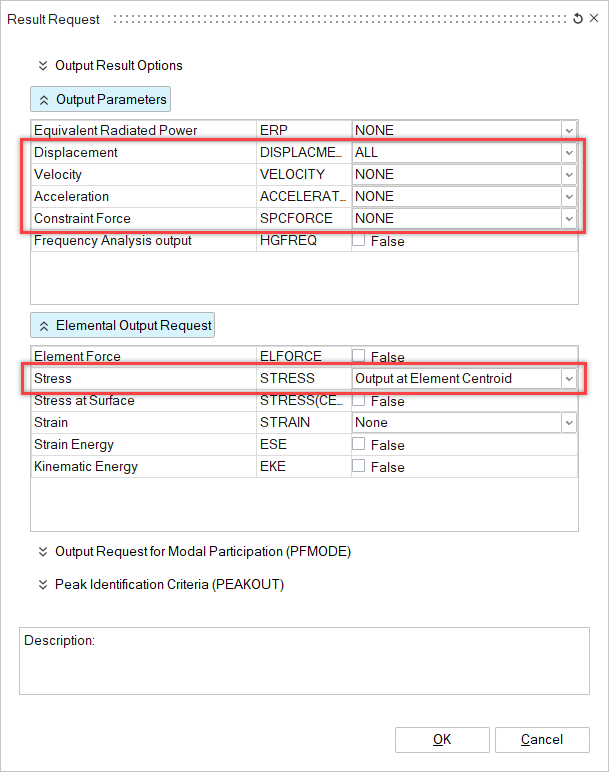

Define Loadcase Parameter and Result Request

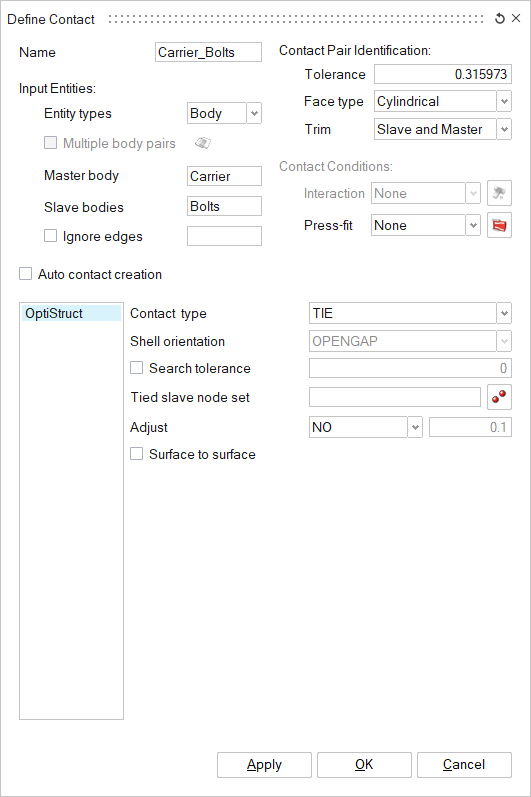

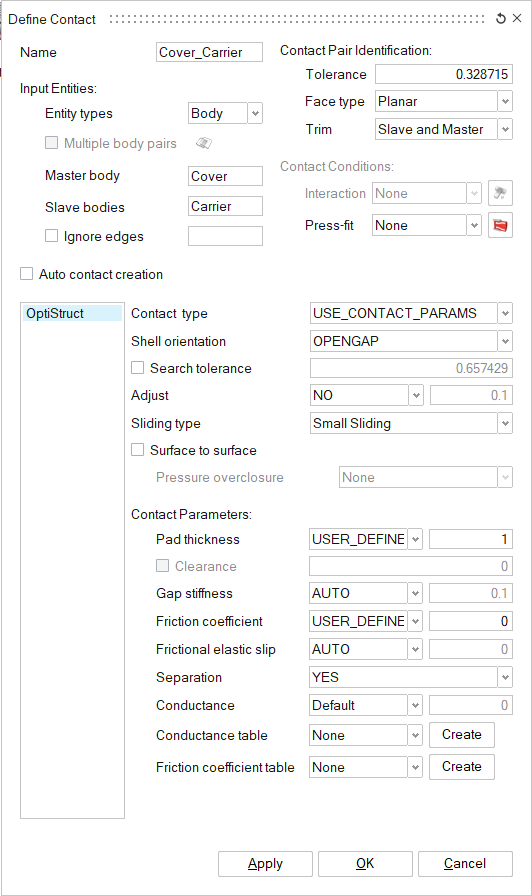

Create Contacts

Solve and View Results

Solve the Solution

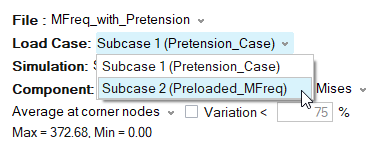

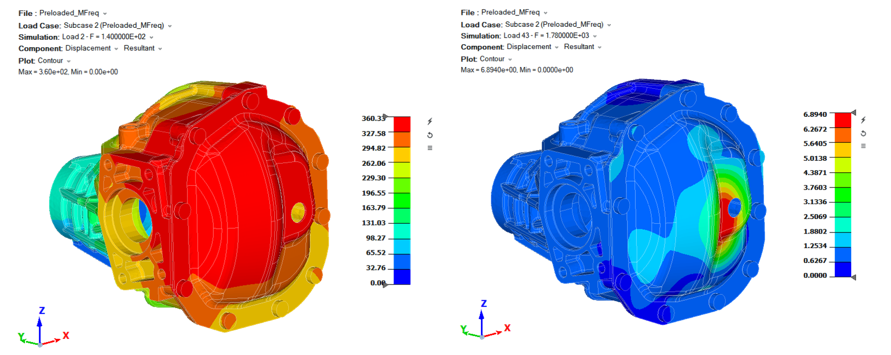

Interpret the Results

After the model setup has been successfully solved, the results are automatically appended to the input model.

Figure 24. Example Displacement Results

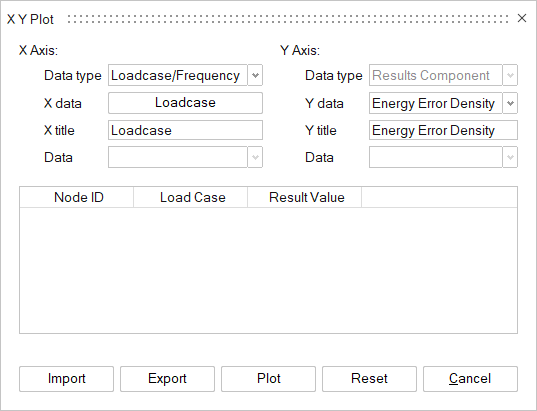

Plot Graph

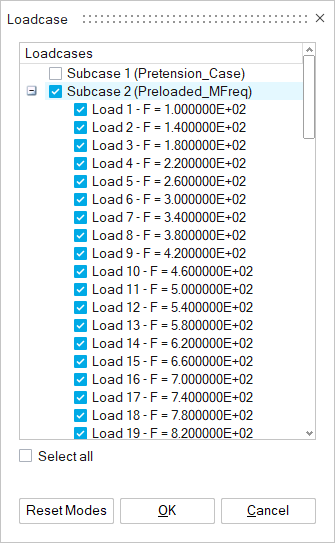

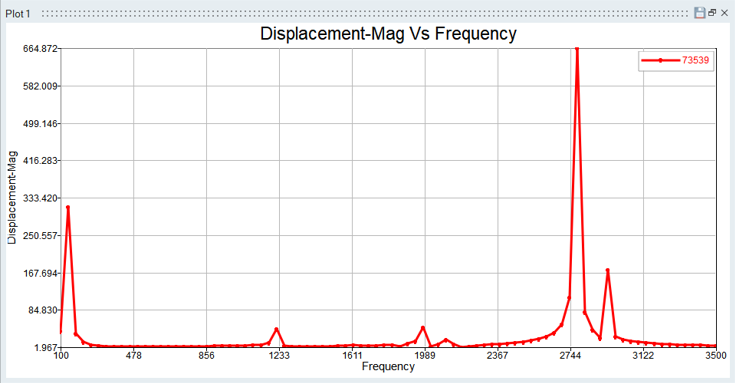

In this step you will plot a graph of resultant displacement at different frequencies of the Preloaded_MFreq subcase.