OS-SL-T: 1010 Brake Squeal Analysis

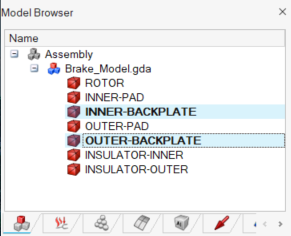

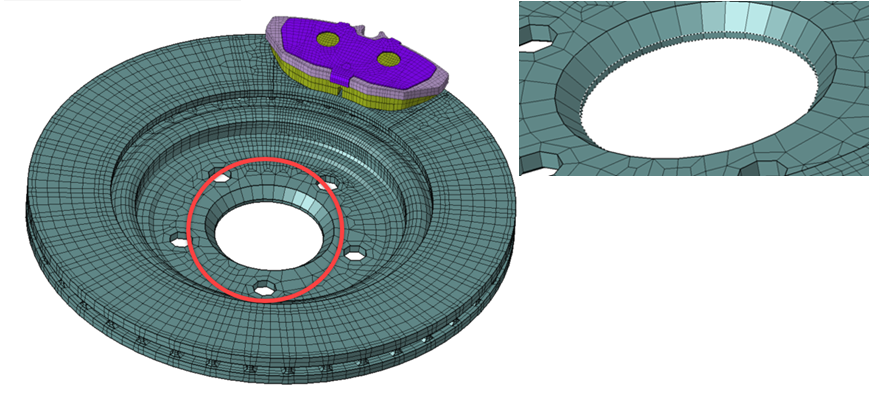

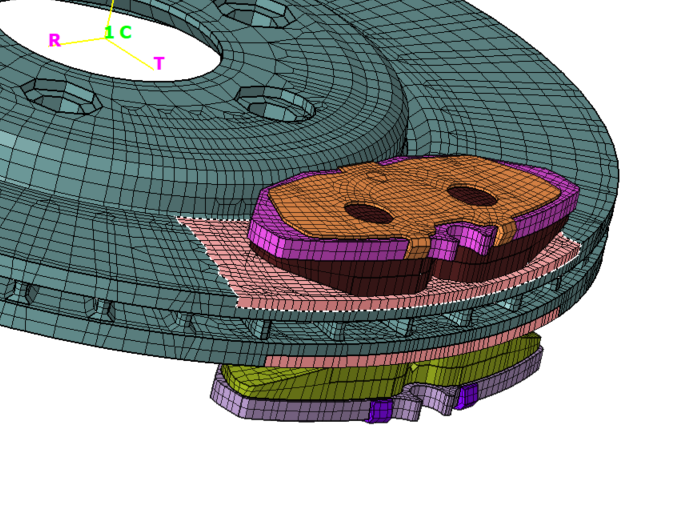

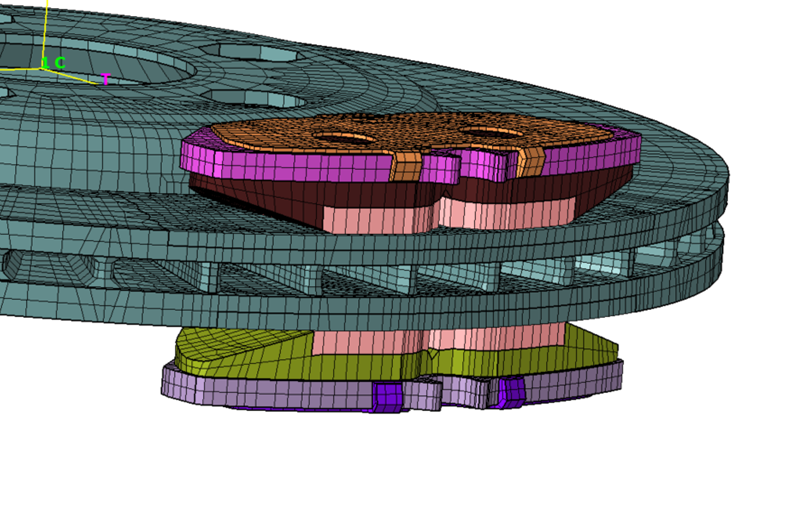

This tutorial demonstrates the creation of finite elements on a given CAD geometry of a brake assembly.

Application of boundary conditions and a finite element analysis of the problem are explained. Post-processing tools are used to determine unstable modes produced during braking.

- Set up the problem in SimLab

- Apply Loads and Boundary Conditions

- Solve the job

- View the results

Launch SimLab

Import the Model

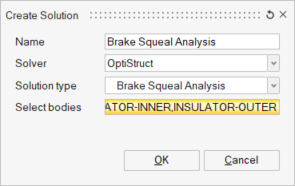

Create Solution

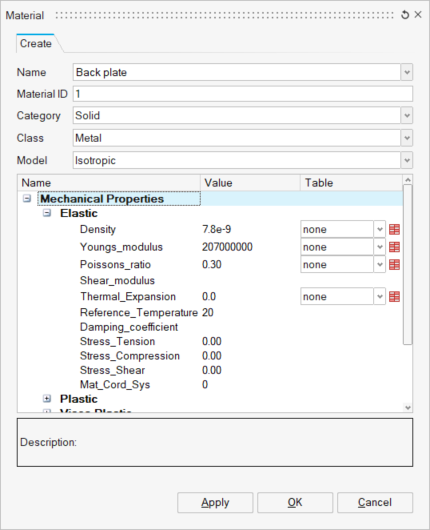

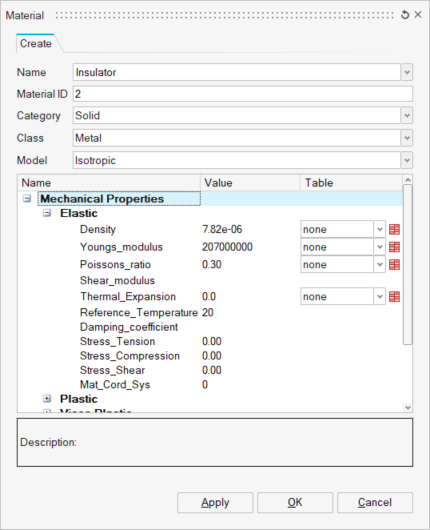

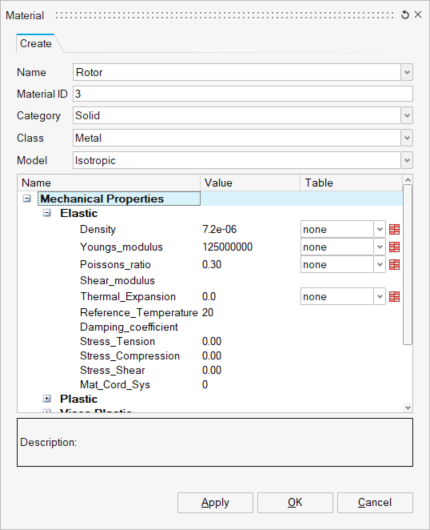

Create Materials and Properties

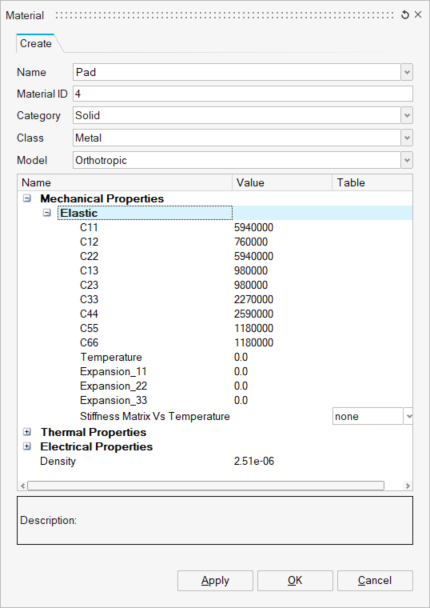

Create Material

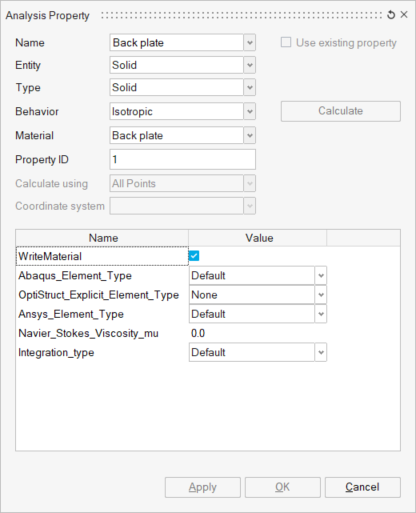

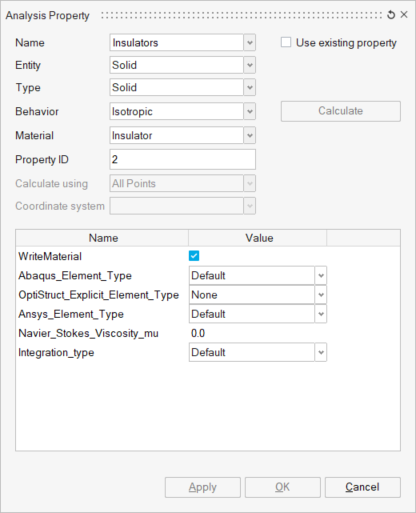

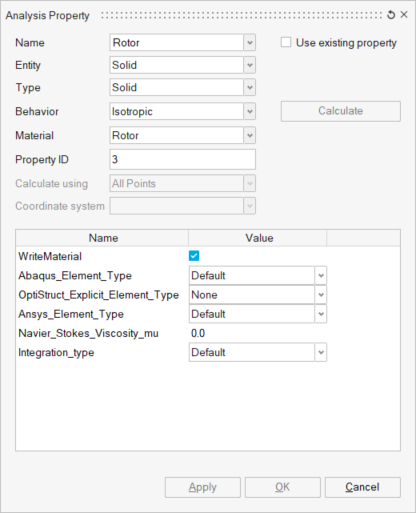

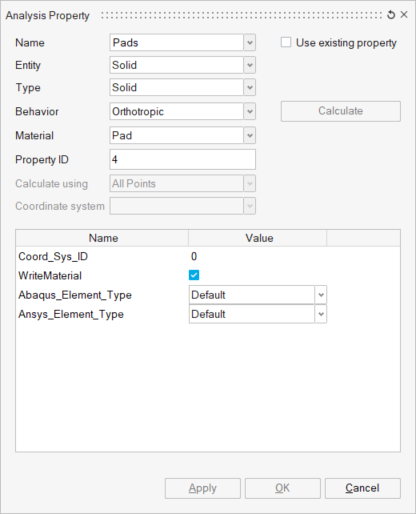

Create Property

Set Up Loads and Constraints

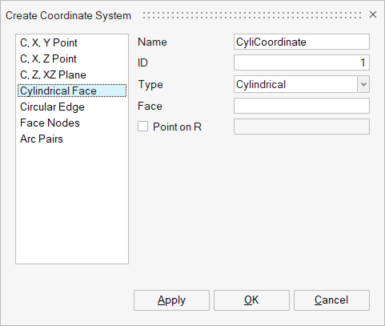

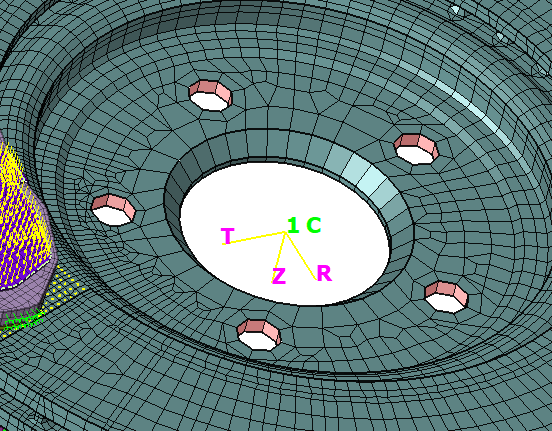

Create Local Coordinate

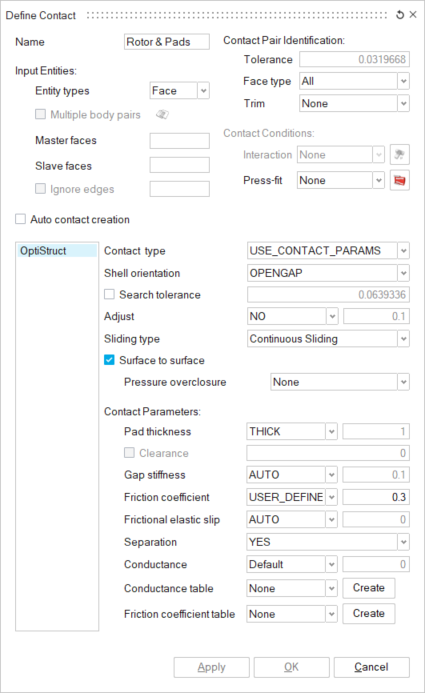

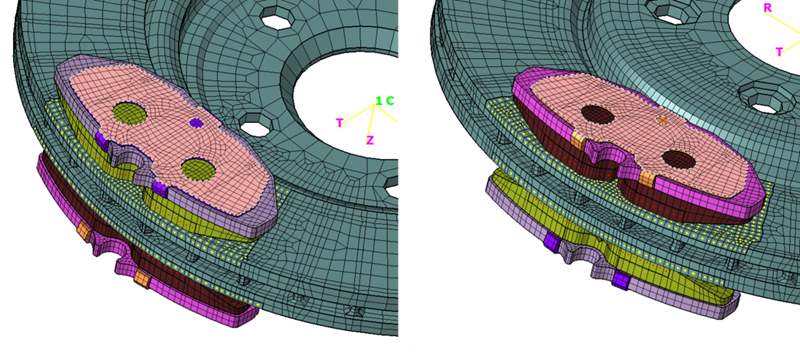

Create Contacts

Contacts are created between the Rotor and Pads to simulate the braking action of the pads against the rotor.

Create Loadcase

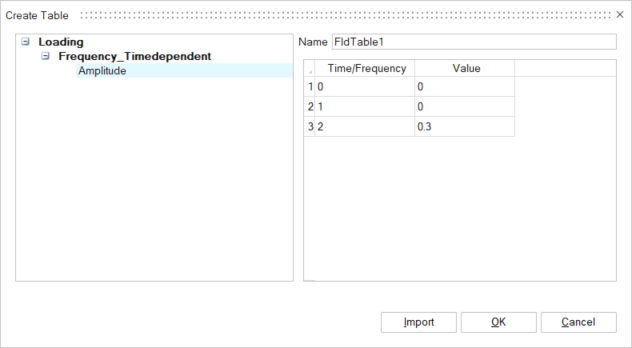

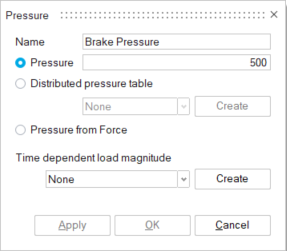

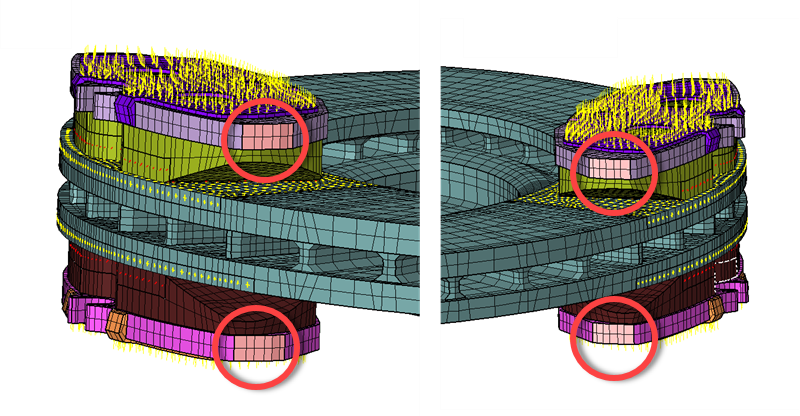

Define Brake Pressure

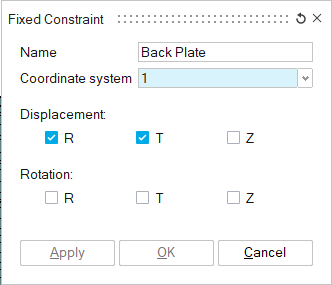

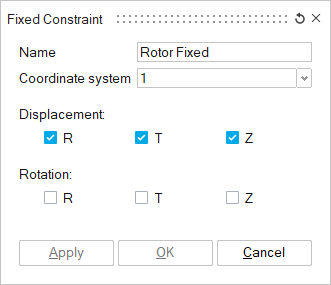

Create Constraints

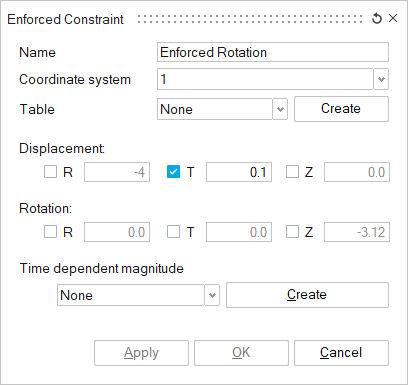

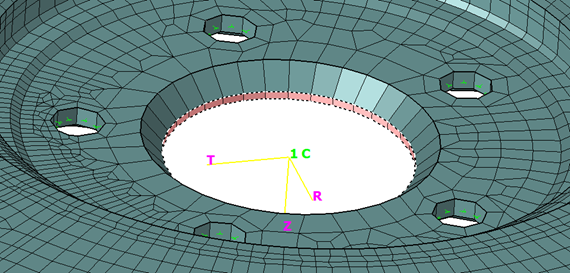

Define Enforced Displacement

The enforced displacement is used to simulate the rotation of the rotor against the brake pads.

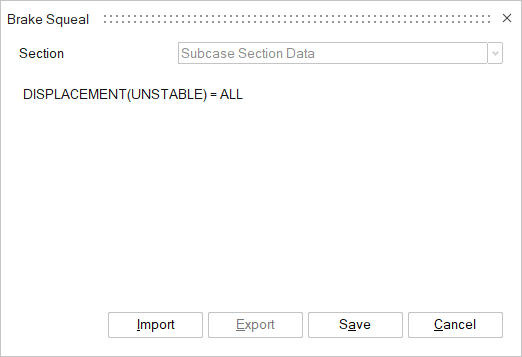

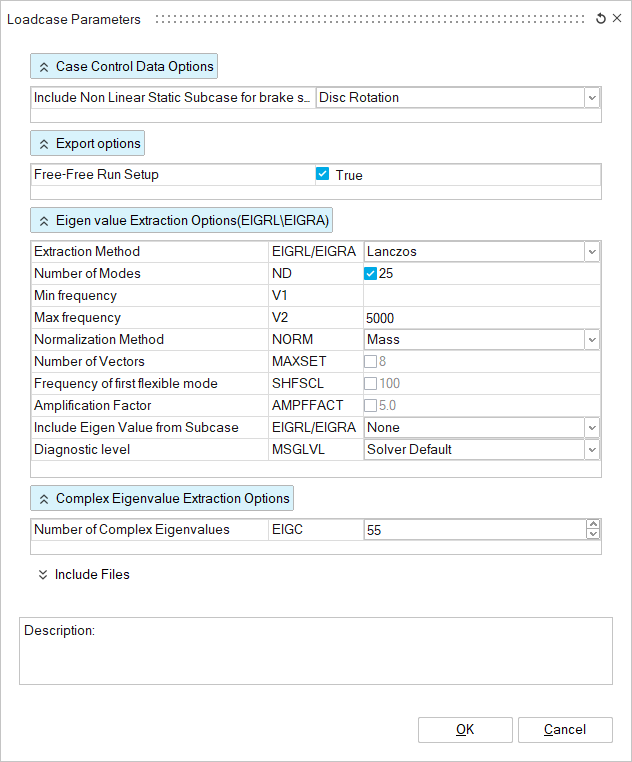

Define Brake Squeal Loadcase

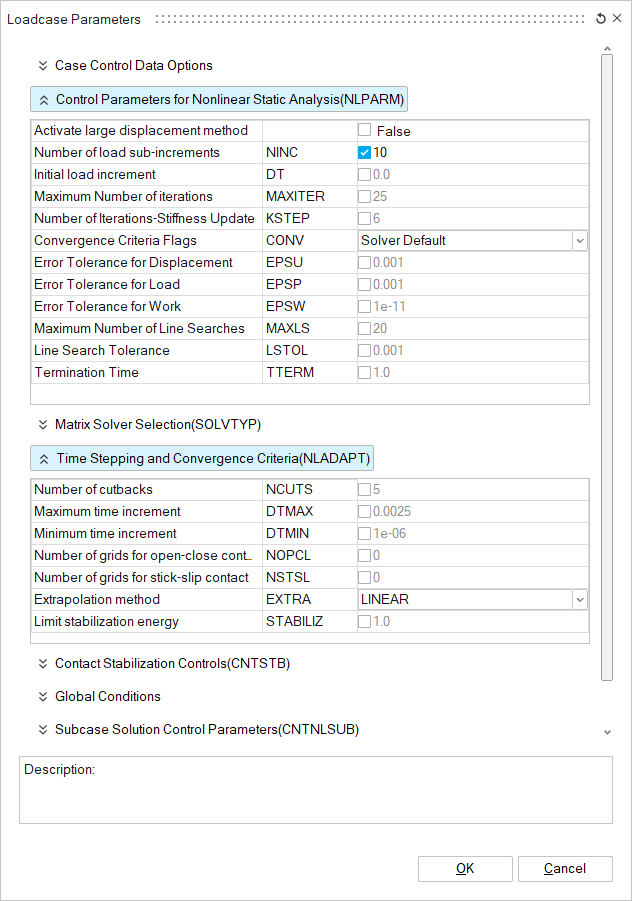

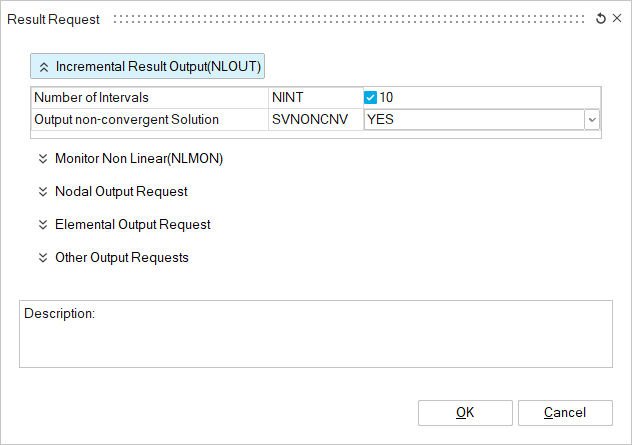

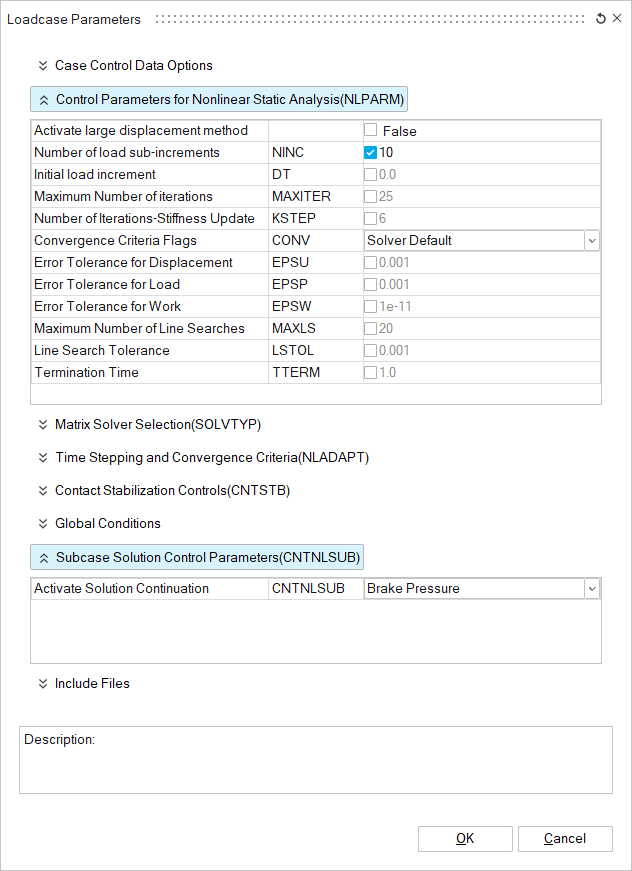

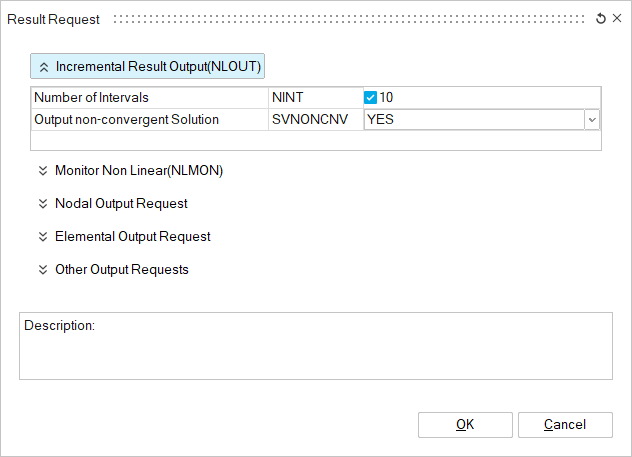

Define Loadcase Parameters and Output Requests

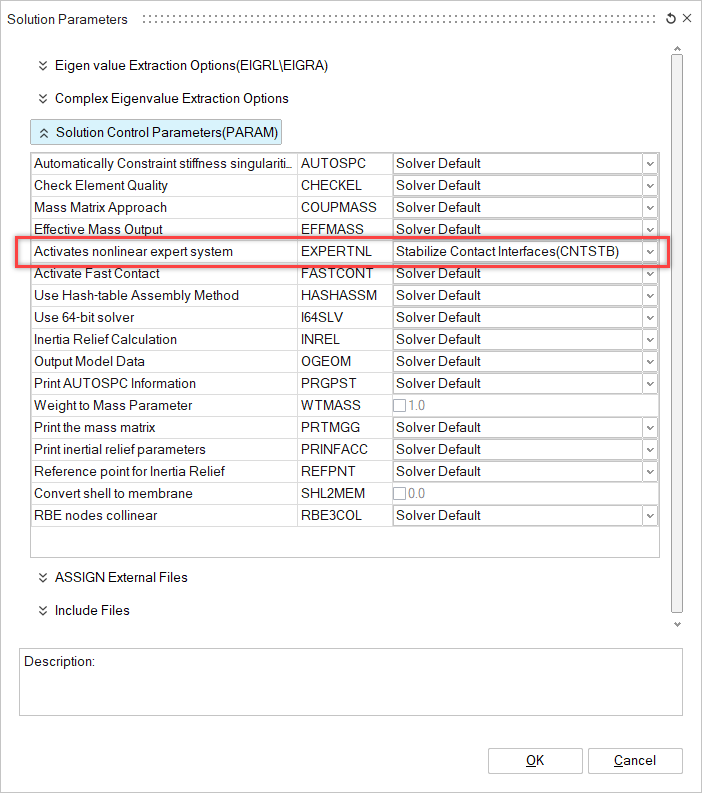

Create Solution Parameters

Solve and View Results

Solve the Solution

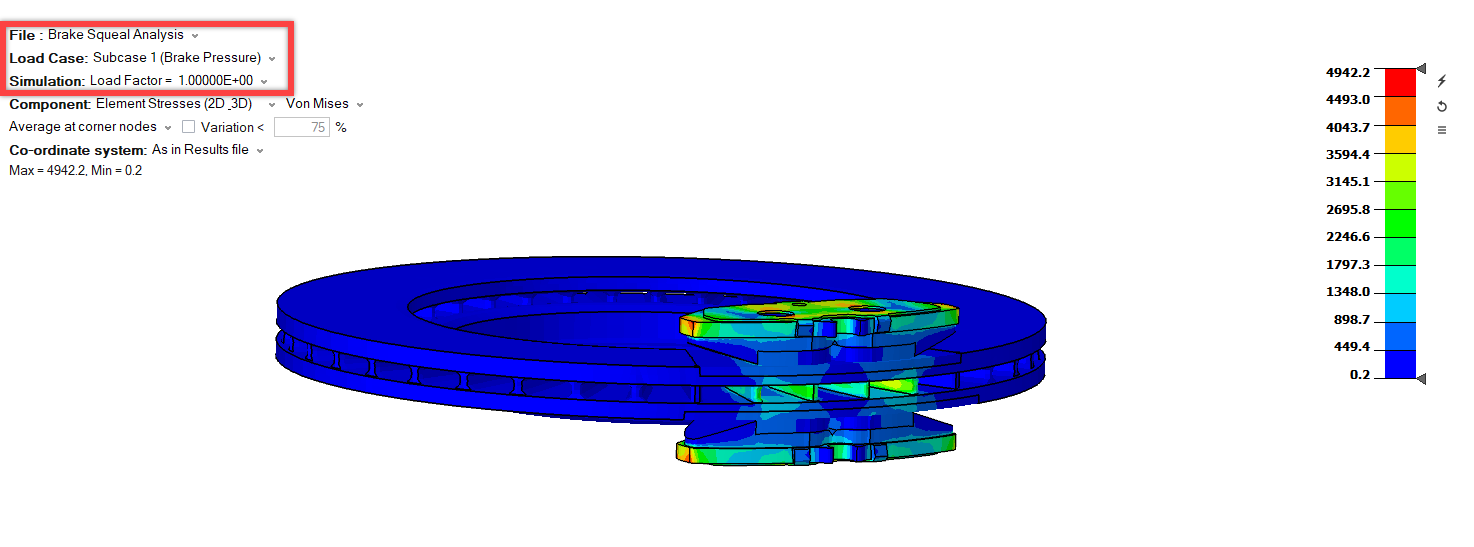

Interpret the Results

Figure 32. Results Loading After Solving