Manage Configurations

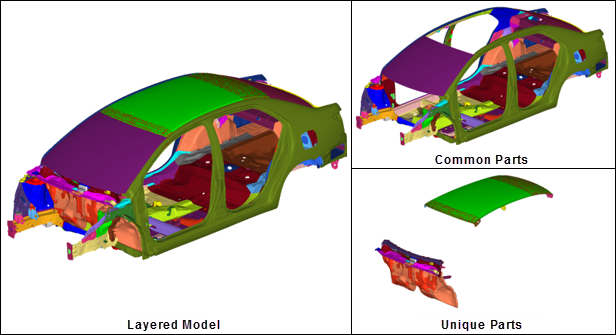

Group common and unique parts/part assemblies together in part sets, and organize parts and part sets that are unique to a configuration.

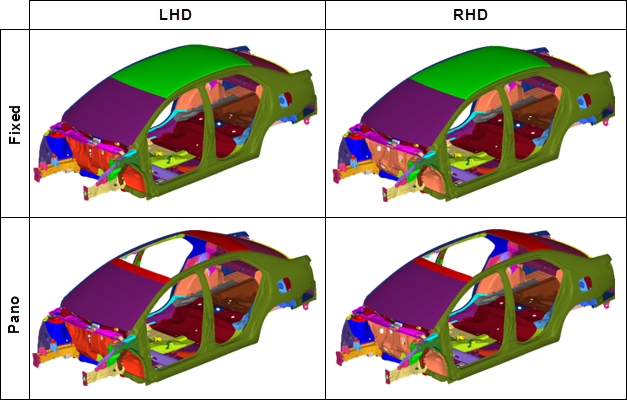

In the traditional model build and assembly workflow, subsystems that contain multiple variants are stored in multiple HyperMesh binary files. This complicates the model build and update process as part updates and revisions will need to be performed on each binary file.

- Left-hand drive (LHD)

- Right-hand drive (RHD)

- Fixed roof (Fixed)

- Panoramic roof (Pano)

All common and unique parts that appear in all configurations for a given subsystem are stored in a single HyperMesh binary file, known as a Layered Model. In a Layered Model, common parts are active in all configurations. Unique parts are active only in a specific configuration. You must deactivate unique parts not appearing in a configuration.