Category: Toolbox > eDrives > eMotors (Legacy) > Loads

Description: The Translational Load block models the dynamic and static behavior of single degree of freedom translational rigid body dynamics of two bodies connected by a linkage mechanism. The linkage mechanism is generic in the sense that it can represent a lever arm or similar device.

This block allows separate specification of load and actuator moving mass properties. Load dynamical properties are reflected back into actuator properties using the linkage ratio. The Translational Load block includes hysteresis, Coulomb friction, viscous friction, static friction, and mass, linear spring, spring preload, and hard stops. These properties can be used simultaneously, or by choosing a 0 value for components can eliminate those components. A disturbance force input (load side) is provided, and can be used to link the Translational Load block with external forces that may be applied from other system components, such as bearing noise and wind gust model. Note that this input is coupled in through the load.

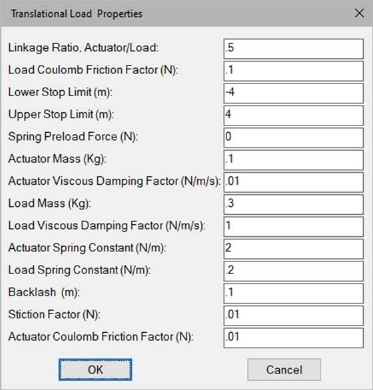

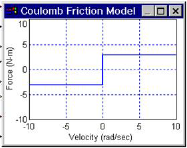

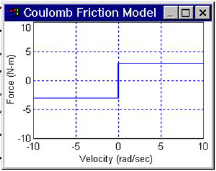

Actuator Coulomb Friction Factor: Indicates the constant directional sensitive force (Coulomb Model). Enter 0 for no Coulomb loading.

Actuator Mass: Indicates the actuator moving mass.

Actuator Spring Constant: Indicates the proportional spring factor that relates the position of the actuator moving mass to the restoring force. Enter 0 (zero) if there is no spring in the load.

Actuator Viscous Damping factor: Indicates the proportional factor of the actuator that relates the velocity to the dissipative force. Enter 0 for no viscous damping.

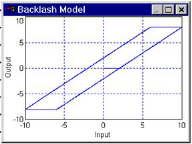

Backlash: Introduces hysteretic backlash in linkage mechanism. Enter 0 for no backlash.

Linkage Ratio Actuator/Load: Defines the mechanical advantage factor between the actuating device and load. Enter 1 for direct coupling between actuator and load; enter a number less than 1 to multiply force; and enter a number larger than 1 to multiply speed.

Load Coulomb Friction Factor: Indicates the constant load directional sensitive force (Coulomb Model). Enter 0 for no Coulomb loading.

Load Mass: Indicates the load moving mass.

Load Spring Constant: Proportional spring factor that relates the position of the load to the restoring force. Enter 0 if there is no spring in the load.

Load Viscous Damping factor: Indicates the proportional load factor that relates the velocity to the dissipative force. Enter 0 for no viscous damping.

Lower Stop Limit: Indicates the minimum hard stop limit.

Spring Preload Force: Indicates the initial restoring (bias) force introduced by load spring. Enter 0 if there is no preload in the spring.

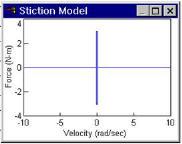

Stiction Factor: Sets the 0 speed, static friction force of the actuator.

Upper Stop Limit: Indicates the maximum hard stop limit.

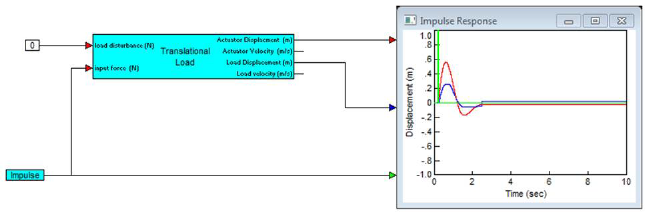

Diagram name: Translational Load

Location: Examples > eDrives > eMotors (Legacy) > Loads

The example shown below is the impulse response of translational masses connected by a gear of ratio of 1:2 with backlash. Each mass is suspended by springs and bearing surfaces that are modeled by a combination of Coulomb, stiction and viscous friction forces. At 0.2 sec, a 10 N impulsive force is exerted on the actuator mass and the assembly can oscillate freely under its own suspension. The topping off of the geared mass is caused by the backlash. Rather than settling to the 0-equilibrium position, both stiction and backlash cause a steady-state offset in the position of the masses.